China OEM Foundry Custom Casting Auto/Machinery Parts in Ductile Iron with CNC Machining

Basic Info.

| Item | Ductile Iron Casting Parts |

| Material | Ductile iron |

| Grey/gray iron | |

| Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc. | |

| Brass Alloy:3600/ 3602 / 2604 / H59 / H62 / etc. | |

| Stainless Steel Alloy:303 / 304 / 316 / 412 / etc. | |

| Steel Alloy:Carbon Steel / Die Steel / etc. | |

| Titanium Alloy: Grade 1/Grade 2/Grade 2 H/Grade 3/Grade 5/etc. | |

| We handle many other type of materials. Please contact us if your required material is not listed above. | |

| Process | Lost wax casting + cnc machining |

| Casting dimension tolerance | CT5-CT8 |

| Casting surface roughness | Ra0.05∼Ra50, as per Customer’s Requirements |

| Casting weight range | 0.01kg-3000kg |

| Casting Size | Max linear size: 1200mm, Max diameter size: 600mm |

| Machining Precision | Positioning accuracy 0.008mm, Rep. position. accuracy 0.006mm |

| Machining surface roughness | Ra0.8~6.3um |

| Max Travel Of Spindle | 1800mmx850mmx700mm |

| Max Turning Diameter | 1000mm |

| Material standard | GB, ASTM, AISI, DIN, BS, JIS, NF, AS, AAR....... |

| Surface treatment | KTL(E-coating), Zinc plating, Mirror Polishing, Sand Blasting, Acid pickling, black oxide, Painting, Hot galvanizing,Powder coating, Nickel plating |

| Service available | OEM & ODM |

| Quality control | 0 defects, 100% inspection before packing |

| Application | Aerospace industry: Jet engine airfoils. Trigger guards and black receiver. Energy: Anvil, gate valve, wellhead control EQP, wellhead EQP. Mining&Heavy machinery: Gear housings,Jaw plates,Rock breaker, Excavator parts Agriculture machinery: Tractor parts, Root grapple rake attachment Pumps&Valves: All kinds of pumps and valves. Transportation: Cylinder heads, Engine support, Suspension arm, Front and Rear brake calipers. |

| Certification | ISO9001:2015, CE, SGS, RoHS, IATF16949 |

| Inspection Equipment | Test Equipment: Spectrum Analyzer, Hexagon CMM, Hardness Test Equipment, Tension Test Machine, E-Coating Testing Equipments, Metalloscope. |

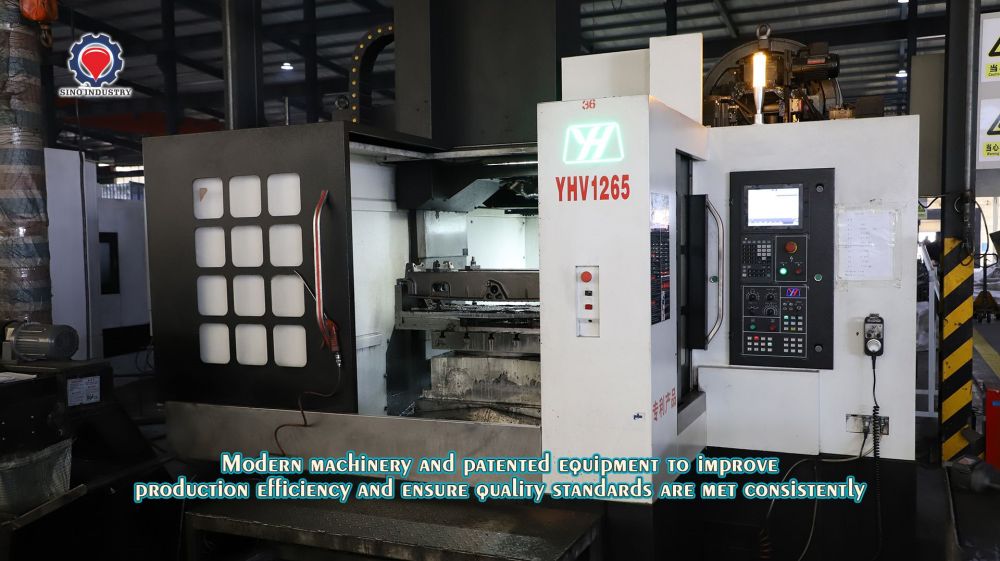

Major Machining Equipments

| Machining Capabilities | |

| Three-Axis turning centre: 1 | Four-Axis Vertical Machine Center: 28 |

| Four-Axis Horizontal Machine Center: 1 | CNC Milling Machine: 6 |

| Vertical Lifting Milling Machine: 4 | Universal Milling Machine: 2 |

| Plane Milling Machine: 2 | Fase Milling Machine: 3 |

| CNC Lathe Machine: 27 | Oblique Guide CNC Lathe Machine: 2 |

| Engine Lathe Machine: 6 | Special Lathe: 5 |

| Radial Drilling Machine: 4 | CNC Porous Drilling Machine: 6 |

| CNC Spcial Drilling Machine: 2 | Cylindrical Drilling Machine: 11 |

Customized design and production

Provide whole engineering solution, covering material, process, finish etc.

Ductile iron(EN-GJS-400-18/450-10/500-7/600-3/700-2/800-2) and gray iron(EN-GJL-150/200/250/300/350) and so on. All available.

Precision machining, diverse heat treatment process and rich surface treatment(Galvanized/Powder coating/KTL(/EPD)/Dacromet/Geomet) available.

Application

1. Engine parts,

2. Auto parts,

3. Machinery Parts,

4. Rail Train parts,

5. Truck Parts,

6. Tractor Parts,

7. Construction Equipment,

8. Agriculture Equipment,

9. Other industrial fields.

10. construction vehicle,

11. forklifts,

12. mining equipment,

13. marine hardware,

14. shipbuilding machinery,

15. power plant device,

16. energy/power facility,

17. petroleum equipment,

18. engineering installation,

19. food equipment,

20. artificial intellegence,

21. Medical instrument,

22. aerospace facility,

23. defensive equipment.

Further Production Process

1. Machining equipment: CNC, Lathe machine, Milling machine, Drilling machine, Grinding machine, and so on;

2. Heat Treatment: annealing, carbonization, tempering, quench, normalization and surface tempering

3. Surface treatment: Powder coating, Chrome plating, Painting, Sand blasting, Nickel Plating, Zinc Plating, Blacking, Polishing, Bluing, etc.

Tooling & Mould

1. Mould life: usually semi-permanent.

2. Tooling Leadtime: 15-25 days, depending on the structure and size.

3. Tooling & mould maintenance: Be responsible by our fatctory.

OEM and ODM service

"No compromise" philosohpy in quality control.

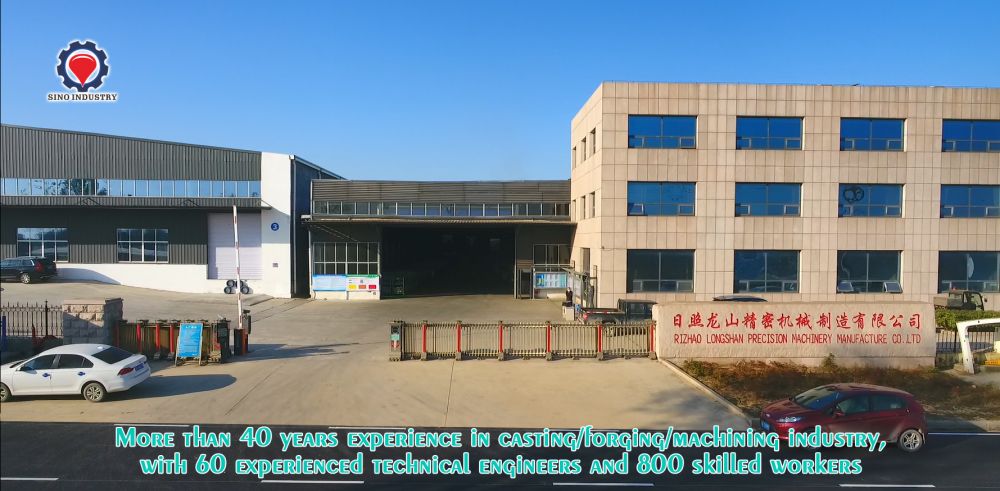

110,000 tons of casting capacity per year, More than 40 years experience in foundry industry!

Our Services

1. Design Services

Our design team has experience in Cardan shafts relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

2. Product Services

Raw materials → Cutting → Forging →Rough machining →Shot blasting →Heat treatment →Testing →Fashioning →Cleaning→ Assembly→Packing→Shipping

3. Samples Procedure

We could develop the sample according to your requirement and amend the sample constantly to meet your need.

4. Research & Development

We usually research the new needs of the market and develop new models when there are new cars in the market.

5. Quality Control

Every step should be a particular test by Professional Staff according to the standard of ISO9001 and IATF16949.