Custom Casting Iron/Steel Parts with CNC Machining for Construction Vehicle/Truck/Machinery

Basic Info.

| Item | Vehicle/Machinery Parts |

| Surface Preparation | Sand Blasting, Plating, Galvanized, Spray-Paint, Passivating, Polishing, Electrophoresis, Machining, etc. |

| Surface Treatment | Shot Blasting/Polishing/Painting/Powder Coating/Anodizing/Zinc Plating/Nickel Plating/Blacking, etc. |

| Surface Roughness | Ra0.05∼Ra50, depends on Customer’s Requirements |

| Heat Treatment | Normalizing, Annealing, Quenching, Tempering, etc. |

| Process | Mold Making, Casting, Machining, Surface treatment, Inspection, Packing, Loading |

| Casting tolerance | CT5-CT8 |

| Coating | Electrophoresis Coating |

| Machining | Lathing/Milling/Turning/Boring/Drillig/Tapping/Grinding, etc |

| Machining tolerance | 0.01mm |

| Application | Construction Machinery/Vehicle/Truck, Mining Machinery, Petroleum Machinery, Engineering Machinery, Excavator, Bulldozer, Loder, Dumper, Self-Dumping/Discharging Truck/Car/Wagon, Crane, Road Roller, Concrete Mixer Truck, Cement Mixer Truck, Concrete Mixer, etc. |

| Package | Bubble Plastic Bag/Polybag/Pallet/Wooden Case, etc. |

| Trademark | OEM |

| Origin | China |

| OEM/ODM service | Available |

Product Description

1. All parts produced according to customer’s CAD and 3D drawings or samples. Please send us the blueprint or drawing artwork along with your inquiry, we will offer you one formal quotation promptly.

2. Materials as below.

Aluminum, Stainless steel, 17-4pH, DERLIN, Ceramics, Carbamide alloy, PEEK etc

3. The surface finished include:

Hardness anodizing black/clear, steel oxidizing dark-blue, electro-polishing, electroless nickel plating, silver plating, golden plating etc.

4. OEM&ODM are welcomed.

5. Packing: Wooden cases, carton or on requirement.

6. Maine equipment:

Machining center, CNC, Lathe, Turning machine, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Tapping drilling machine, Wire cutting machine etc.

7. Testing facility: Coordinate measuring machine, projector, roughness tester, hardness tester, concentricity tester. Height tester, .

8. Part size: Diameter from 0.5mm to 150mm

9. Tolerance: +/-0.01mm

10, Lead time: 5-25days after the confirmation of sample

11: Minimum Order: Comply with customer's demand

12, Delivery way: EXPRESS, BY SEA OR BY AIR on your requirement.

These products are showed here only to present the capability of our business activities,

Our company specialized in manufacturing and designing of various non-standard precision parts, our service cover mechanical engineering, electronic engineering, semiconductor, tele-communication, medical equipment, automation equipments etc. We invested advanced manufacturing equipments(such as high-speed CNC Machining Center, Grinding machines, Milling machines, NC lathe, Stamping machine, Wire-Cutting machines)and quality testing machines(such as coordinate measurement machine, Micro-projector and Height Gauge etc. ) we can also provide one-stop shopping OEM.

All parts can be machined with tiny tolerance, precise dimensions and a smooth surface. Roughness typically considered to be the high frequency, short wavelength component of a measured surface.

It's our pleasure to serve you if we get your inquiry with detailed specification and drawings, we will submit our competitive offer ASAP and provide you premium quality porducts.

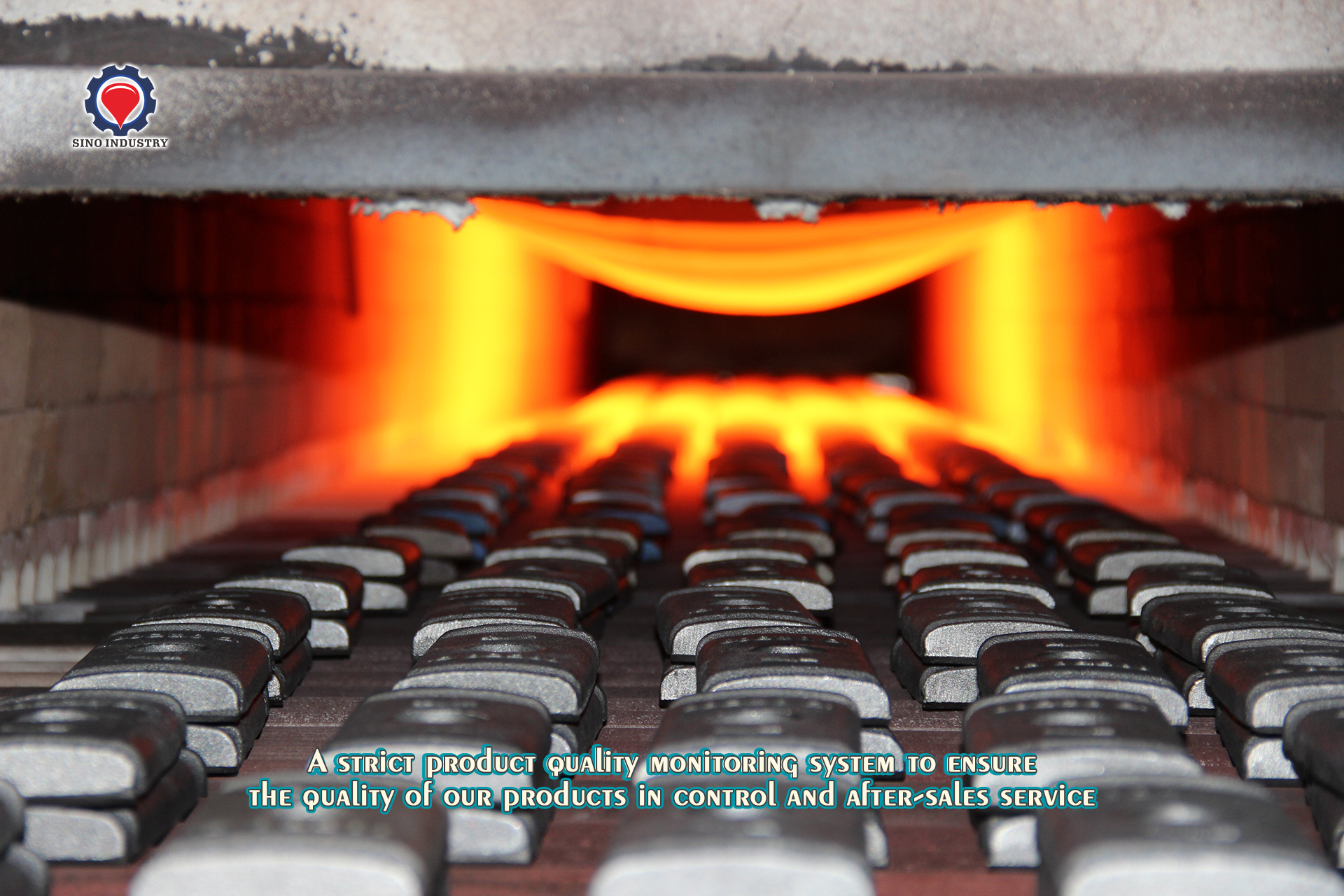

Casting (metalworking)

In metalworking, metal is heated until it becomes liquid and is then poured into a mold. The mold is a hollow cavity that includes the desired shape, but the mold also includes runners and risers that enable the metal to fill the mold. The mold and the metal are then cooled until the metal solidifies. The solidified part (the casting) is then recovered from the mold. Subsequent operations remove excess material caused by the casting process (such as the runners and risers).

Our Products and Services

The products that are exhibited in this site are just sample parts we once machined according to customers' drawings, or the ones that we are able to machine. We do custom machining service for customers and quote the prices according to the drawings of specific parts provided by the customers.

Procedures for Customizing Parts are as Follows:

1.Customer provides 2D or 3D drawings;

2.We quote the prices according to your drawings(we can also design the parts according to your specific requirements);

3.Orders are confirmed by both parties;

4.We start to put your parts into machining;

5.We package and deliver the parts the customer;

Mission and Vision

Our Mission Statement

Our company endeavors to be a company with a fully integrated solution to produce high precision parts and delight customers worldwide.

Our Vision and Organizational Behavior

Based on a global mindedness, the company is dedicated to supplying products and CNC machining service of the highest quality, yet at competitive prices for worldwide customer satisfaction.

We keep advancing with ambition and youthfulness. We enjoy work and encourage open communication, and strive constantly for a harmonious flow of work.

Manufacturing Capabilities

Our capabilities include CAD modeling, CNC Milling, Manual Milling, Manual Turning, Precision Grinding, Heat Treating and Assembly.

Our facility has CNC machining centers, CNC lathes, CNC longitudinal lathes, slow-speed wire cutting machines and so on, providing much manufacturing flexibility. Our engineers select the ideal equipment for an application based on the geometry, material, and volume of the part being machined to provide customers with premium quality parts at the best possible price.

We are able to hold very tight geometric tolerances for diameter, true position, profile, and flatness and so on. Our milling machines also offer through-the-spindle coolant and Renshaw touch probes. They also have tool setters that can be used for tool breakage detection for longer run parts.

Quality Inspection

In addition to our stringent in-process controls, all components must pass a thorough final inspection. we have a coordinate measuring machine, salt spray testing machines, profile projectors and other precision measuring devices, etc.

All testing is conducted in a 20 degree Celsius climate-controlled inspection room and the CMM is calibrated to GB/T 16857.2-2006 (ISO10360-2:2001) standards. All components and sub-assemblies are 100% inspected, identified with a logo if required and a final inspection is generated pertaining to all the critical dimensions.

Customers' CAD drawings can be directly imported in the coordinate measuring machines (CMM) for a direct comparison to the dimensions that are taken from the physical part.

Why Choose Us

1.Rich experience and resources of various manufactures

After 40 years experience accumulated in this industry, our company has enormous resources of various manufacturers and distributors. Not only we are able to supply large quantity order, but also we can organize small quantity complex order as well.

2.Excellent service before purchasing

Since we have our own repair workshop, we know what the best cost-effective spare parts are. According to clients' circumstances, we will recommend most suitable parts for them.

3.Guaranteed quality

Most products which we are selling are used in our own repair workshop; therefore the quality is really secured.

1)A complete range of specifications and a great variety of models.

2)Durable in use and dependence performance.

3)Sincere service and prompt shipment.

4)Competitive price and excellent performance.

5)Adapt to customer's specific request and also can make new model according to your samples or designing draft.