Customized Iron/Steel Parts for Mining Equipment/Machinery Made by ISO Manufacturer

Basic Info.

| Item | Auto/Machinery Parts | |

| Casting Unit Weight | 0.01KG-3Tons | |

| Casting Standard | ISO ,DIN, AISI, ASTM, BS, JIS, etc. | |

| Casting Workpieces Size | Customized with the drawing you offered. | |

| Casting Workpieces Color | Silver, black, white, bronze, champagne, green, gray, golden yellow, nickel, or customized. |

|

| Surface Roughness | Ra0.05-Ra50, or as per Customer’s Requirements. | |

| Heat Treatment | Normalizing, Annealing, Quenching, Tempering, etc. | |

| Casting Material | High grade ductile iron(QT1050-6)/(QT800-5)/(QT600-5), Grey iron, Stainless steel, Carbon steel. | |

| Casting Process | Sand Casting | Iron based coated sand |

| Coated sand | ||

| Clay sand | ||

| Resin sand | ||

| Investment Casting | ||

| Lost Foam Casting | ||

| Vacuum process casting | ||

| Surface Finish | Sand Blasting, Anodizing, Powder coating, Wood grain, Polishing, Brushing, Electrophoresis. |

|

| Machining | Lathing/Milling/Turning/Boring/Drillig/Tapping/Grinding, etc | |

| Machining tolerance | 0.01mm | |

| Inspection Equipment | Test equipment: Spectrum Analyzer, Hexagon CMM, Hardness test equipment, Tension test machine, E-coating testing equipments, Metalloscope. | |

| Dimension Inspection | Coordinate Measuring Machine (CMM),Calipers, Height Gauge, Micrometer Calipers, Inside Caliper Gauge, Angle and R Gauge,customized gauge, etc. | |

| Product application | Our products are widely used in many industries, such as automobile, truck, train, railway, fitness equipment, agricultural machinery, mining machinery, petroleum machinery, engineering machinery, shipbuilding, construction and other power equipment. | |

| Lead time | 30-45 days after down payment. | |

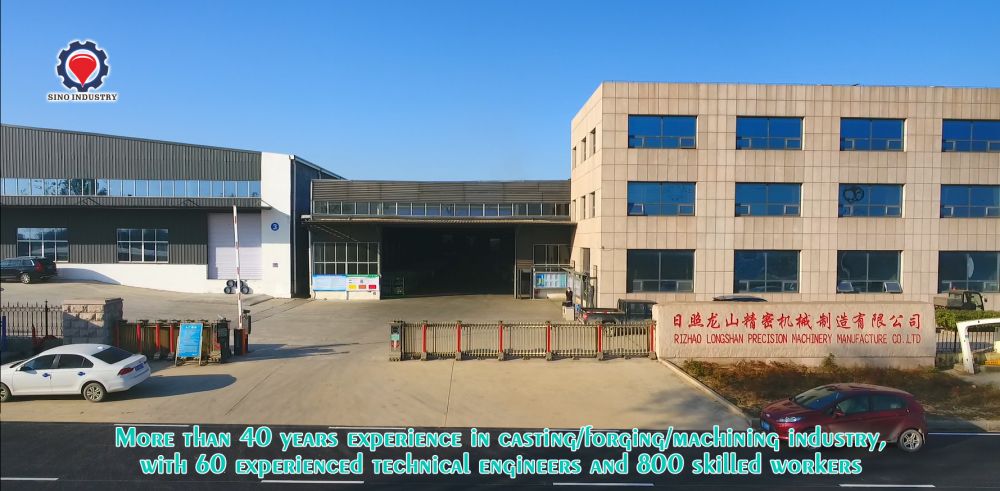

Company Profile

Established in 1980, Sino Industry and Trade Company is a leading foundry manufacturer specializing in the design, research, development, manufacture and marketing in the foundry industry in China. It is a factory integrating research, development, production and sales, mainly engaged in the casting and processing of ductile iron, grey iron and steel. The annual production ability reaches 110,000 tons.

The main product is cast iron auto parts, fitness equipment, Cooker set, hand tools, train and railway parts, etc.

It is equipped with workshops for casting, core making, cleaning, machining, spraying, packaging, etc., with supporting facilities such as measurement, physical and chemical inspection.

Our company specializing in the production of all kinds of Agricultural Machinery Parts, Metal Machining Parts, Animal-Drawn Plough& Plow, Ductile Iron Casting, Grey Iron Casting, Auto Spare Parts, Industrial Machinery Accessories, Mechanical Wheel Casters, Railway Fittings, Agricultural Tools Accessories, Building Decoration Accessories , Metal Stamping, Manhole Covers, Pipeline Valves and Accessories, Fireplace Accessories. They widely used in agricultural machinery, engineering machinery, car shipping, mining machinery, construction, pump valve and other industries, our company has complete casting, stamping, spraying production line .

Manhole Covers are manufactured for construction and public use. arious production and processing equipment more than 100 units, annual output of 30000 tons. we can also supply goods with the material according to customers requirement, most of our products are casting and machining products .

We have passed the “ISO 9001” and “ IATF 16949” International Quality Management System Certification.

In order to ensure the quality of the orders, our independent QC members to carry out strict inspection at each stage:

(1)Incoming material inspection

(2)Inspection of work-in-progress

(3)Finished product inspection

(4)Random warehouse inspections

All of our operations are strictly compliant with ISO 9001: 2008 guidelines We own automated casting lines, CNC machining, CMM inspection, spectrometers and MT testing equipment, X-ray. To benefit from our strong OEM/ODM capabilities and considerate services, contact us today. We will sincerely create and share success with all clients.

Production

1. ISO9001-2015 certified factory.

2. Advanced euipments and over 40 years experience.

3. Price: Competetive price, Precision made. Experience & Reasonable QC that you can reply on.

4. Processing: Precision made. Experience & Reasonable QC that you can reply on. Each part would be given 100% test and tryout before shipment.

5. Adequate supply capacity. Punctual delivery time.

6. Products: Investment Casting / Precision Casting Parts / ball Valves / stainless steel sand casting parts / machinery parts / CNC machining parts, Steel Investment Casting / lost wax / casting / die casting/ forging

7. Progress of precision casting: Investment casting

8. Precision Casting materials: Ductile iron, Grey iron, Stainless steel, Carbon steel, iron steel, alloy steel.

9. We can do different kinds of surface treatment after casting, such as machining, polishing, and plating.

10. All sorts of precision casting parts: Marine casting parts, auto parts, machinary casting parts, pump parts, hardware parts.

Quality Control

We have a full set of quality control system to guarantee quality. Depending on the products, we make different Item Testing Plan, Manufacturing procedure etc.

● Raw material control

● Chemistry spectrum analysis

● Mechanical property

● Metallographic analysis

● Ultrasonic testing

● Magnetic testing

● Radiographic testing

● Dimension inspection

● Visual inspection

● Penetrant testing

● Leak testing

● Hardness test

● Micro-structure tester after heat treatment

FAQ

1.Q: Are there any special capabilities that your company has?

A:We have passed the certification of ISO9001:2015 and IATF16949, our production and quality is ensured strictly by this certifications. For any high quality products, we can do the PPAP and Control Plan as per customer's request.

We have our own CMM, we can inspect precision dimensions that the normal calipers can't measure, and ensure the quality.

2.Q:What are the maximum sizes and weights that you can produce for forging, casting & machining?

A:The maximum size for stainless steel parts could be 700*700*700mm, and the weight could be 200kg. The maximum size for carbon steel parts could be 1000*1000*1000mm, and the weight could be 350kg.And we could also produce sand casting parts at our cooperation company. The material is gray iron and ductile iron. For gray iron, the material grade could be HT150, HT200, HT250, HT300, HT350. For ductile iron, the material grade could be QT400, QT450, QT500, QT600. The maximum size for sand casting could be Φ1500*2000mm, and the weight could be 4000kg. For the above size and weight is the maximum we could do, and for the smaller parts we could also produce.

3. Q:What are all the types of materials you can supply for forgings and castings ?

A:Material Available: For casting, the material could be ductile iron, grey/gray iron, stainless steel, carbon steel, alloy steel. For forging, the material could be ductile iron, grey/gray iron, stainless steel, carbon steel, alloy steel, aluminium, brass.

4. Q:What kind of payment conditions do you accept ?

A:For samples, we need 100% sample fee to be paid before production. Or if there is mold, we need 50% mold cost prepaid, the balance 50% mold cost to be paid before shipment. We will send you Inspection Reports and photos of samples for you to approve before shipment.

For mass production, 30% T/T down payment before production, balance 70% against B/L copy.

5. Q:How long does it take to quote ?

A:Usually we can quote out in two days after we receive RFQ with all the necessary details.

6. Q:Do you provide modification service by CAD or 3D drawings from sample ?

A:Yes, we provide modification services if you want to change the design.

7. Q: I don't have any drawing, can I send you a sample for quotation and production?

A:Yes, we can create drawings as per the original samples offered by customers.

8. Q: What kind of format of drawings can you accept?

A:PDF, CAD, JPEG, JPG, or 3D files such as IGS, STEP, Solid-works.