Lost Wax/Die Casting Carbon Steel Investment Casting Agricultural Machinery Spare Parts

Product Details

| Specification | As per your PDF, CAD, Proe drawing or samples |

| Casting Weight | 0.01kg-3000kg |

| Casting Standard | ISO, ASTM, AISI, EN, DIN, NF, JIS, BS, etc. |

| Casting Tolerance | CT6-CT9 |

| Surface Roughness | by Customer′ S Requirement |

| Heat Treatment | Normalizing, Annealing, Quenching, Tempering, etc. |

| Casting Material | Carbon steel,Alloy steel, Stainless steel, high temperature alloy, etc. |

| Casting Process | Precision casting, Investment casting, Lost wax casting,dewaxing casting,Vacuum Casting(compound process production line, and silicon sol production line) |

| Surface Preparation | Sand Blasting, Plating, Galvanized, Spray-Paint, Passivating,Polishing,Electrophoresis, ,Machining,etc. |

| Inspection Equipment | Spectrograph, Metallographic analyzes, Universal Strength Tester, Hardness Tester, Impact Test Machine, Pressure Testing Machine, Magnetic Particle Inspection Machine. |

| Dimension Inspection | Coordinate Measuring Machine (CMM),Calipers, Height Gauge, Micrometer Calipers, Inside Caliper Gauge, Angle and R Gauge,customized gauge, etc. |

| Manufacturing process | Drawing or Samples→Tooling making→ Wax pattern making → Inspection wax pattern → Tree Assembly→Shell making → Dewaxing → Shell roasting and pouring → Cutting and sand blasting →Heat treatment → Machining→Final quality control→Packing →Shipping |

| Application | Our products cover a wide range of industries including forklift, automobile & truck,train & railway, agricultural machinery, mining machinery, Petroleum machinery, construction machinery , shipbuilding, construction, valve and pumps, electric machine, power equipment,gas turbine, turbocharger, aero-engines and so on. |

Our comparative advantage

1* Mature one-stop service system.

We provide real one-stop service for all customers

(1)we are the source manufacturers, and our price has an absolute advantage.

(2)We have our own technology department to solve all-round problems related to product technology.

(3)We have a complete production line, products from raw materials to finished products are under our control.

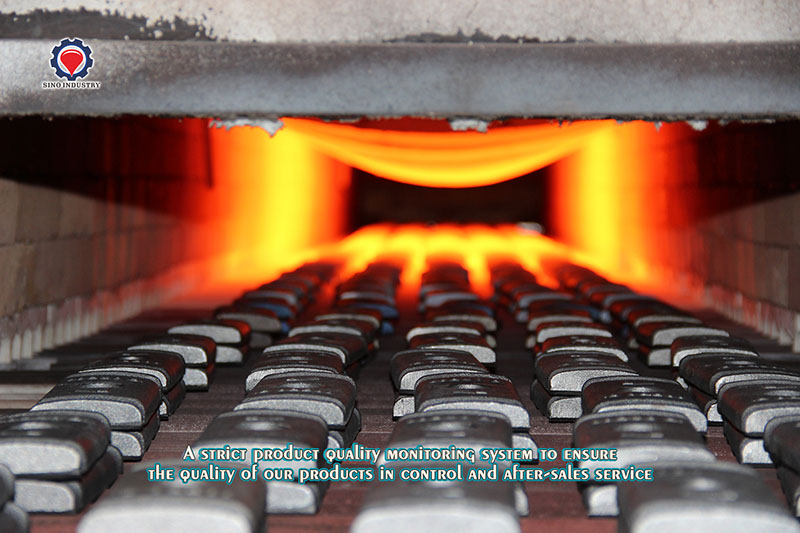

(4)We have a strict product quality monitoring system to ensure the quality of our products and after-sales service.

(5)Based on customer needs, in the beginning of product development, offer a solution, products design, by structural component designed to casting parts, optimize product design, reduce costs and creating more value for customers.

(6)Use casting simulation analysis system software, try our best to ensure the success of one-time trial sample.

2* Modern machinery and patented equipment.

Advanced testing equipments, strict quality control system, to ensure us constantly, stably to provide high-quality products for customers.

We have more than 30 kinds, 400 sets in total, including 60 sets of four/five-axis machining center (CNC) and 2 sets of digital special machines designed with double main axle boxes, of mechanical equipments related to casting, forging, stamping, punching, molding, machining, processing and surface treatment. First-class equipments significantly improve production efficiency and product quality.

3* Rich experience, special skill, optimal solution

A senior engineering technical team with special skills and rich experience for over 40 years in product design, casting, forging and machining fields. Have special technology and skill to solve and handle special material, special structure, special defect and special processing. Based on customer needs, in the beginning of product development, offer a solution, products design, by structural component designed to casting parts, optimize product design, reduce costs and creating more value for customers. We provide real one-stop service and optimal solution for customers.

Our advantage of cnc machining

| Business Type | Beyond the Manufacturer and strong Milling Machining Parts organized ability in the industrial |

| Benefits | 1. Deeper industrial experience at CNC machining parts service for more than 10-years,our customer's requirement is our 1st priority. 2. 2D or 3D files is available; 3. We trust the quality priority and we insist the good quality should be based on the customers' satisfied; 4. Without any MOQ requirement; 5.Faster delivery time; 6. Customized size and specification /OEM available 7. Near Shanghai Port |

Parameter

| Processing | CNC center, CNC milling, CNC turning, drilling, grinding, bending, stamping, tapping, |

| Surface finish | Polishing, sandblasting, Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, imitation gold-plated, |

| Tolerance | 0.05mm~0.1mm |

| QC System | 100% inspection before shipment |

| Drawing format | CAD / PDF/ DWG/ IGS/ STEP |

| Packaging | Plastic bag/Standard package / Carton or Pallet / As per customized specifications |

| Payment Terms | 30 -50%T/T in advance, 70-50% balance before delivery; Pay Pal or Western Union is acceptable. |

| Trade terms | EXW, FOB, CIF, As per the customer's request |

| Shipment Terms | 1)We prefer DHL or TNT express or other air freight between 1kg-100kg.

2) we prefer sea freight more than 100kg or more than 1CBM 3) As per customized specifications. |

| Note | The CNC machining parts are usually custom-made based on the customer's drawings and samples. So we need the Down Payment |

Products Description

Investment casting is one of the oldest manufacturing processes which are also referred to as lost-wax methods. It produces precision parts in metal. This process simply involves making a wax pattern which is fundamentally a copy of the anticipated part in iron, steel, copper, and aluminum.

In this process of Investment casting, the pattern is covered in a ceramic material and then removed when the heat is applied. Just like other casting processes, the mold is filled with molten steel and when the mold is broken away from the solid steel, it produces the casting parts.

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have a full inspection and routing inspection during mass production---In-process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Major products and Applied industry

As a professional manufacturer specializing in the design, development, manufacture and marketing in the foundry industry. Our company is one of Chinese automobile manufacturer giants FAW/FOTON/SINOTRUK/SANY/HOWO/SHACMAN designated supplier for customized casting&machining parts.

The castings produced by us are widely used in various industries, such as construction vehicles, trains, railways, forklifts, agricultural machinery and other mechanical equipments such as machinery accessory, machine accessory, industrial accessory, industry accessory, equipment accessory, mechanical accessory, machining accessory, cnc machining accessory, cnc accessory, precision accessory, high performance accessory, device accessory, facility accessory, engine accessory, motor accessory, precision machine accessory, valve accessory, valve body, valve shell, valve casing, valve housing, gate valve, ball valve, connector, solenoid valve, pipe fittings, control valve, floating ball valve, pneumatic valve, industrial valve, gas valve, flange gate valve, directional valve, hydraulic control valve, butterfly valve, gearbox, gearbox accessory, gearbox body, gearbox shell, gearbox casing, gearbox housing, oil cylinder, water pump, impeller, pump impeller, stainless steel pump, centrifugal pump, slurry pump, sewage pump, electric pump, submersible pump, high pressure pump, chemical pump, pressure pump, water pump set, self-priming pump, garden pump, deep well pump, oil pump, fountain pump, pond pump, mud pump, single suction pump, fuel pump, hydraulic pump, hydraulic pump accessory, hydraulic spare accessory, pump spare accessory, water pump accessory, diesel pump, vacuum pump, pump accessory, pump body, pump shell, pump housing, pump casing, pump cover, auto pump, car pump, automotive pump, automobile pump, vehicle pump, truck pump, lorry pump, farm machinery accessory, farm machine accessory, farm vehicle accessory, farm truck accessory, agricultural machinery accessory, agriculture machinery accessory, agricultural machine accessory, agriculture machine accessory, agricultural vehicle accessory, agriculture vehicle accessory, agricultural truck accessory, agriculture truck accessory, combine harvester accessory, mining machinery accessory, mining machine accessory, mining truck accessory, mining vehicle accessory, mining equipment accessory, machine spare accessory, hardware accessory, marine hardware, petrochemical accessory, petrochemical machine accessory, petrochemical machinery accessory, petrochemical equipment accessory, petrochemical device accessory, petrochemical facility accessory, petrochemical installation accessory, petroleum accessory, petroleum machine accessory, petroleum machinery accessory, petroleum equipment accessory, petroleum device accessory, petroleum facility accessory, petroleum installation accessory, energy accessory, energy machine accessory, energy machinery accessory, energy equipment accessory, energy device accessory, energy facility accessory, energy installation accessory, power machine accessory, power machinery accessory, power equipment accessory, power device accessory, power facility accessory, power installation accessory, power plant accessory, power plant machine accessory, power plant machinery accessory, power plant equipment accessory, power plant device accessory, power plant facility accessory, power plant installation accessory, shipbuilding accessory, shipbuilding machine accessory, shipbuilding machinery accessory, shipbuilding equipment accessory, shipbuilding device accessory, shipbuilding facility accessory, shipbuilding installation accessory, engineering accessory, engineering machine accessory, engineering machinery accessory, engineering equipment accessory, engineering device accessory, engineering facility accessory, engineering installation accessory, high quality accessory, high performance accessory, diesel engine, cast iron accessory, casting accessory, sand casting accessory, cast iron, cast steel, steel casting, iron casting, cast steel accessory, etc.

FAQ

Q1: Where can I get product&price information?

A1: Please send us an inquiry on the page or e-mail, we will feedback to you with all information you concern about.

Q2: How soon can I get samples and how much is the fee?

A2: Depending on your specific project, it usually takes 10 to 20 days. The sample fee depends on your parts drawings, and the fee will finally be returned to your bulk order.

Q3: How to enjoy the OEM services?

A3: Usually, base on your design drawings or original samples, we give some technical proposals and a formal quotation to you, upon your approval, we start the production process.

Q4: Can you make machining parts based on our samples?

A4: Yes, we can make measurements based on your samples to make drawings for machining parts making.

Q5: Is it possible for buyer to learn the production progress at any time without visiting your factory?

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the casting&machining progress.

Q6: Will my drawing safe after you get it?

A6: Yes, we can sign the NDA before you send us your drawings.