Made in China OEM Casting/Machining Ductile Iron for Auto/Machinery Parts Customized by ISO Manufacturer

Basic Info.

| Item | Ductile Iron Parts |

| Surface Preparation | Sand Blasting, Plating, Galvanized, Spray-Paint, Passivating, Polishing, Electrophoresis, Machining, etc. |

| Surface Treatment | Shot Blasting, Polishing, Painting, Powder Coating, Anodizing, Zinc Plating, Nickel Plating, Blacking, etc. |

| Heat Treatment | Normalizing, Annealing, Quenching, Tempering, etc. |

| Process | Mold Making, Casting, Machining, Surface treatment, Inspection, Packing, Loading |

| Casting Tolerance | CT5-CT8 |

| Coating | Electrophoresis Coating |

| Machining | Lathing, Milling, Turning, Boring, Drillig, Tapping, Grinding, etc |

| Machining Tolerance | 0.01mm |

| Certification | ISO9001:2015, CE, SGS, RoHS, IATF16949 |

| Inspection Equipment | Test Equipment: Spectrum Analyzer, Hexagon CMM, Hardness Test Equipment, Tension Test Machine, E-Coating Testing Equipments, Metalloscope. |

| Application | Automobile, Heavy Truck, Light Truck, Commercial Vehicle , Forklift, Construction Machinery/Truck/Vehicle, Farm Vehicle/Machinery/Truck, Agriculture Machinery/Truck/Vehicle, Mining Machinery, Marine Hardware, Train, Railway, Petroleum Machinery, Engineering Machinery, Shipbuilding, Power Equipment, etc. |

| Package | Bubble Plastic Bag, Polybag, Pallet, Wooden Case |

| Trademark | OEM |

| Origin | China |

| Loading Port | Qingdao Port |

| Annual Supply | 1000000 Pieces |

| Sample | Available |

| OEM/ODM Service | Available |

Product Description

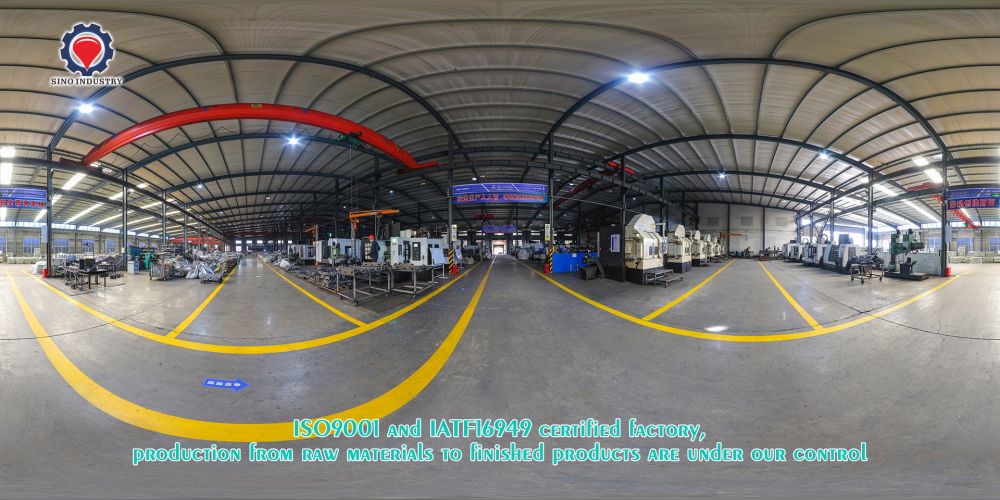

Professional OEM/ODM casting/machining factory.

Die casting category: precision auto/machinery parts manufacturing

Die-cast aluminum alloy: ADC12, A360, A380, AlSi12(Cu), AlSi9Cu3(Fe), AlSi10Mg, etc.

Die-casting machine tonnage: 800T-2000T, 8 automatic die-casting production lines

Aluminum die-casting mold: die-casting mold design, stamping mold design and machining fixture design

Surface treatment of aluminum parts: shot blasting, vibration polishing, heat treatment, impregnation, polishing, painting, anodic oxidation, electrophoresis, electroplating, powder spraying

CNC precision machining: Mazak, Hyundai, Haas vertical and horizontal machining centers, CNC lathes, etc.

1. Product material: aluminum alloy, zinc alloy

2. Surface treatment: chrome plating, sandblasting, spraying, anodizing, powder spraying, electrophoresis

3. Delivery time: 30~45 days for mass production.

4. Applicable to various industries: automobiles, machinery, valves, pneumatics, etc.

5. The whole process includes: molds, die-casting molds, CNC machining, CNC milling machines, stamping, injection molding, painting and powder coating, custom assembly of cubs. Based on high-quality products, excellent service, reasonable prices, and timely delivery, we welcome customers, business associations and friends from all over the world to contact us to seek cooperation and achieve mutual benefit and win-win results.

Our Equipments

| Prcessing Equipements | ||||

| No. | Eqipment name | Quantity(sets) | Precision | Max processing size |

| 1 | CNC Planer type milling machine | 1 | 0.005mm | 2000*1300mm |

| 2 | 4 Axis CNC milling machine | 1 | 0.005mm | D30mm to 40mm |

| 3 | CNC milling machine | 14 | 0.005mm | 800*450mm,600*350mm |

| 4 | Milling machine | 14 | 0.02mm | 780*350mm |

| 5 | CNC lathe machine | 3 | 0.002mm | D450*500mm |

| 6 | Lathe machine | 2 | 0.01mm | D360*750 |

| 7 | Plane grinding maching | 4 | 0.005mm | 350*200*150mm |

| 8 | High speed WEDM | 4 | 0.02mm | 700*400*500 |

| 9 | Low speed WEDM | 2 | 0.01mm | |

| 10 | Hydraulic sheet metal bending machine | 1 | VC67Y-30T*1600mm, Liter pressure:300kN | |

| The main test equipment | |||||

| Number | Equiment name | Specification | Quantity(set) | Brand | Origin |

| 1 | Electronic Altimeter | 0-600mm | 1 | TESR | Switzerland |

| 2 | Image Measurement Instrument | 250*150mm | 1 | JATEH | China |

| 3 | Rockwell Apparatus | HR-150A | 1 | Shidai | China |

| 4 | Surface roghness comparison Specimens | 1 | Weifang | China | |

FAQ

Q1. How many years does your company deal in autoparts?

A: Established in 1980, Sino Industry and Trade Company is a leading foundry manufacturer specializing in the design, research, development, manufacture and marketing in the foundry industry for more 40 years.

Q2. What is your company major products?

A: Our main products are brake system and suspension system.

Q3. Are you a factory or trading company?

A: We are a factory integrating research, development, production and sales. Our company wholly owns a subsidiary production factory named “Rizhao Longshan Pricision Machinery Manufacture Co., Ltd.”, which possesses superior production equipment, strict and effective quality assurance system, excellent and perfect detection means, rich and abundant technical force.

Q4. What is the MOQ?

A: Negotiable.

Q5. What is the lead time?

A: 30~45days for mass production.

Q6. What is the packaging?

A: Neutral packing, wooden case, or customized.

Q7. What is the payment terms?

A: T/T, L/C, WEST UNION, PAYPAL.

Q8. What is the payment method?

A: 30% deposit before production, 70% balance before shipment.

Q9.Can you help to ship the products?

A: YES. We can help to ship the prodccts through customer forwarder or our forwarder.

Q10.Can you offer free samples?

A: It depends on the sample costs.

Q11.Can your company make as per samples?

A: YES, we can make according to customer’s sample.

Q12.What are your major market?

A: North America, Europe the Middle East, Africa and Southeast Asia.