OEM Casting Motor/Engine Parts with CNC Machining for Construction Vehicle/Machinery/Truck

Basic Info.

| General Information of Our Products and Services | |

| Scope of Typical Parts | Construction Machinery/Vehicle/Truck, Heavy Truck, Forklift, Mining Machinery, Engineering Machinery, Shipbuilding, Excavator, Bulldozer, Loder, Dumper, Self-Dumping/Discharging Truck/Car/Wagon, Crane, Road Roller, Concrete Mixer Truck, Cement Mixer Truck, Concrete Mixer, etc. |

| Scope of Workpiece Materials | Metal materials: ductile iron, grey iron, stainless steel, aluminum, aluminum alloy, magnesium alloy, brass, mild steel, Cr12, SKD11 and so on. |

| Surface Roughness | Ra0.05∼Ra50, Depends on Customer’s Requirements |

| Machining Methods | Milling, turning, medium-speed wire cutting, slow-speed wire cutting, grinding, turning and milling forming) |

| Tolerance Ranges | Metal Machining: tightest +/-0.003mm, depending on the products. Non-metal Machining: tightest +/-0.01mm, depending on the products. |

| Workpiece Size Range | Milling: 1020mm*510mm*500mm Turning: Ø0.5mm-Ø250mm*500mm |

| Surface Treatment Options | Aluminum alloy: black oxidation, natural color oxidation, color oxidation, hard oxidation, micro arc oxidation, conductive oxidation. Stainless steel: passivation, black zinc plating, blackening, PVD. Steel: blackening, bluing, chromium plating, nickel plating, black zinc plating, color zinc plating, white zinc plating, paint copper: gold plating, silver plating, blackening, passivation, etc. |

| Certification | ISO9001: 2015, CE, SGS, RoHS, IATF16949 |

| Inspection Equipment | Test Equipment: Spectrum Analyzer, Hexagon CMM, Hardness Test Equipment, Tension Test Machine, E-Coating Testing Equipments, Metalloscope. |

| Lead Time for Prototypes | It takes about 15 days for production, depending on the product. |

| Lead Time for Formal Orders | It's determined according to order quantity and other requirements. |

| MOQ | Negotiable |

| Payment Terms | Normally, T/T 30% is to be prepaid and balance paid before shipment for the first order. |

| Transportation | Ocean freight with customs declaration. |

| Packaging | Foam sealing, independent carton, self-sealing bag, oil paper, vacuum packaging, wooden case, etc. |

| Port of Delivery | Qingdao Port or as per customer's requirements. |

Product Description

Brief introduciton of sand casting:

Sand casting is perhaps the oldest and most commonly used type of metal forming in the marketplace today. It is capable of forming both large and small parts and can be used for a number of different materials.

We have green sand castings, resin sand casings and water glass sand castings in both ferrous and non-ferrous materials.

Perhaps the most common green sand castings would be made from either grey iron or ductile iron. We can supply these castings from approximately 0.05Kg to approximately 15000 Kg and up to 5000mm x 2000mm x 1500mm in size for the largest part. Molding methods range from floor hand molding, jolt squeezer lines and automatic molding lines. With this variety of molding methods we are able to accommodate the weight, size and quantity the customer requires.

Steel sand castings are available both as water glass sand castings and resin sand castings, and are available in plain carbon, alloy and stainless steels. In the category of steel sand castings the smallest available part would be approximately 1Kg while the largest would be approximately 20 tons. Steel castings smaller than the 1Kg range would be made from investment casting(lost wax casting) method.

Non-ferrous sand castings are also available. The molding process used is green sand and we can accommodate requests for castings weighing from 0.01 Kg to 3,000 Kg. The alloys that are available include copper base and aluminum base alloys.

First article layouts and spectrometer material certifications are provided with all first article samples. Specialized inspection reports can be done per customer request.

A variety of secondary operations can be performed on all three types of sand castings. They include shot blasting, heat treatment, machining,surface treatment, assembly services and even custom packaging.

| Materials and casting weights for different sand casting methods | |||

| Sand casting method | Green sand casting | Resin sand casing | Water glass sand casting |

| Materials used in different method | Grey iron,Ductile iron, Aluminum and copper alloy |

Grey iron,Ductile iron, Carbon steel,Alloy steel, Stainless steel | Carbon steel,Alloy steel, Stainless steel |

| Weight range | 0.05-15000Kg | 0.5-18000Kg | 5-20000Kg |

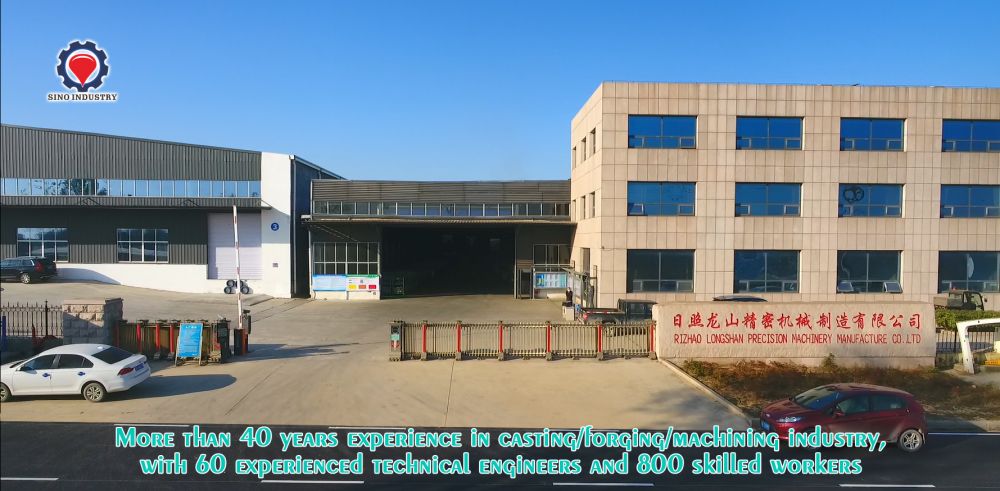

About us

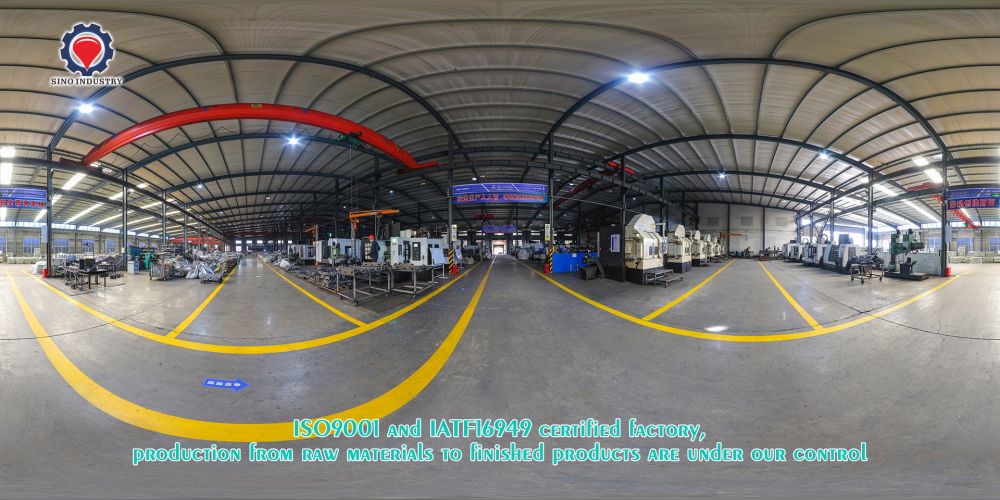

Our factory has more than 800 employees with strong technical faculty, including 60 engineers. Embracing advanced flanges and tube supporting the production lines, the company has high technology skills in forge and press, IF push system, machining, cold forming, hot extrusion and heat treatment . In addition, the company also has the capabilities of chemical analysis, metallurgical analysis, physical experiment, nondestructive testing and other advanced detection. Therefore, our company could produce different ranges of stainless steel, alloy steel, carbon steel flanges, elbows, tees, reducers, caps, big bend, the socket series of pipeline components with high and medium pressure, and various specifications, material steel pipe according to international and domestic standards.

The products have been widely used in marine, power generation, natural gas, chemicals, chemical, petroleum, pharmaceutical, coal, aviation, construction, water supply and many other fields. We develop and maintain direct business dealings with the United States, Russia, Australia, Brazil, Dubai, Paraguay, Chile, Argentina, and other countries and regions. Now the company has grown into a star company gathered production, manufacturing, domestic and foreign sales of other diversified businesses.

The company specializes in the design, research, development, manufacture and marketing in the foundry industry for more than 40 years, and commited to offer high quality products with competitive prices and excellent service worldwide. Focuses on creating more value for customers. We assist companies in reaching across cultural and geographical distances to dramatically reduce manufacturing costs, while maintaining product quality and on-time delivery. We have advanced equipment and facilities: Bending machine, Punching machine, NCT Punching Machine, CNC machine, and Spot welding machine. And we have a group of experienced and professional management staff members. Keeping on improving our technology and quality control system, we are developing steadily. "Seeking Survival on Quality and Development on innovations" is our slogan. We believe that we are able to maintain the spirit of loyalty and increase customer satisfaction.

FAQ

Q1:Do you make customized products based on our designed drawings?

Re:Yes, we are a professional metal fabrication factory with an experienced engineering team to make custom products according to clients'drawings.

Q2: Will my drawing be safe after you get it?

Re:Yes, we will not release your design to third party without your permission. And we can sign the NDA before you send us the drawing.

Q3: Is the price the same for different surface treatments?

Re: no, the price of the plating is higher than the anodic oxidation.

Q4. If I choose plating process, all color can do?

Re: no, plating process with current technology can't be all color, can only do several conventional colors, such as: black, white, gray, silver, gold, etc.

Q5: How do you provide OEM/ODM service?

Re: Customer's logo can be embossed on our case. But you need to send us the logo in AI or Cdr or PSD format. Our designer will make a drawing for your checking and approval.

Q6: What is your best price?

Re: Our products have a quite wide price range for different types. Thus please contact us online, we will be glad to offer you one formal quotation upon receipt of your detailed requirements.

Q7: What are the payment terms for sample cost and order amount?

Re:1) T/T 30% downpayment. 70% at sight of copy of B/L;

2) Paypal , Ali pay through trade assurance order;

3)Irrevocable L/C 100% to be drawn at sight;

3) other payment methods can be discussed.

Q8: Can I pay a visit to your factory?

Re: Anytime you are welcome to visit us. We would like to pick you up at Rizhao or Qingdao Airport or Hotel, all is free.