OEM Factory Custom Casting Parts with CNC Machining for Auto Engine Mounting Bracket

Product Details

| Item | Custom Ductile Iron Casting Auto Engine Mounting Bracket |

| Processing | Investment casting, Sand Casting, Machining |

| Available Material | cast iron, stainless steel, copper, aluminum alloy etc. |

| More Processing | CNC Machining,Plastic Injection,Stamping,Die Casting,Welding,Forging, Mould Making,etc |

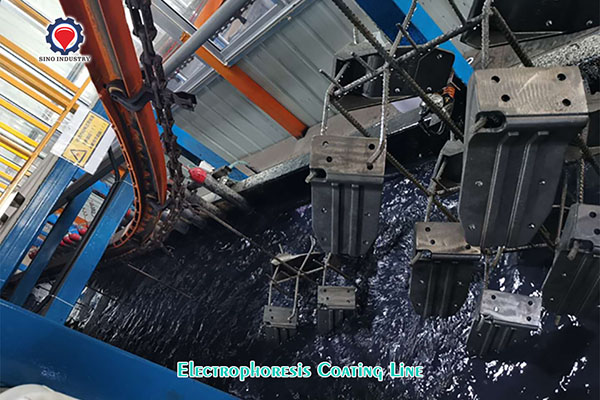

| Surface Finish | Powder Coating, Anodizing, Polishing, Electric-plating, Pvd Coating, Hot Dip Galvanizing, E-coating, Tin Plating, Nickel Plating, Chrome Plating, Dacromet, Enamel Coating etc. |

| OEM | Available |

| Application | All kinds of cars,valve, pump, machinery,home appliance,electronic products,electric appliance,construction,computers,power switches,miniature switcher,architecture,hardware and plastic molds,sports equipment and gifts,and more. |

| Manufacturing Type | Precision Machining, CNC Milling, CNC Lathe Turning, Tapping, Drilling, Grinding, Stamping, Deep Drawing, CNC Punching, Laser Cutting, CNC Bending, Die Casting, Welding etc |

| Industries Served | Aerospace, Automotive, Agriculture, Construction, Electrical, Electronic, Home Appliance, Medical,Marine, Machinery, Furniture, Food, Lighting,Telecommunication etc |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG,DXF,IGS,STEP |

| QC | 100% Strict Inspection For Every Processing |

| One-stop Service | Custom Design, Fabrication, Assembly And Delivery |

Custom Ductile Iron Casting Auto Engine Mounting Bracket is one of our key products from our production line.

Material could be from ductile iron or grey iron.

Products ranges

Engine System: Transmission mount, engine mounting, insulator bracket;

Shock Absorbed Mount/Strut Mount

Suspension Parts: Control arm, control arm bushing, ball Joint;

Cooling System: Fan blade;

Exhaust System: Exhaust Pipe Support, Flexible Hose, Radiator Absorbed Bush

Car Accessories: Car mat.

Car Series:

Japanese brand: Honda, Toyota, Nissan, Mazda, Mitsubishi, Isuzu, Subara, Suzuki, Daihatsu

European brand: Audi, Skoda, Benz, BMW, Peugeot, FIAT, Volkswagen, Renault, Opel, Volvo, Citroen

American brand: Ford, Buick, Jeep, Chevrolet, Chrysler, GM, Dodge

Korean brand: KIA, Hyundai, Daewoo

If you are interested in any of our products, please don't hesitate to contact us, more information will be forwarded to you upon receipt of your specific inquiry.

What is an engine mounting bracket?

An engine mount is exactly what it sounds like - the part of your car that holds the engine in place. Because your transmission and engine are bolted together, you need mounts to keep them from moving around. Usually, there's one mount holding the transmission and two or three holding the engine.

Is an engine mount/bracket important?

If you are having a car mount issue, it is very important to get it looked at by a professional mechanic and repaired as soon as possible. A failing motor mount can lead to serious engine damage and will also greatly impact the performance of the vehicle. It is very unsafe to drive with a broken motor mount.

Engine mounting bracket

We produce engine mounting bracket, steering gear bracket, leaf spring bracket, steering knuckle, bumper bracket, balanced suspension, etc. according to customer’s drawings/samples/requirements.

As a professional OEM/ODM casting/machining factory, we provide real one-stop service and optimal solution for customers. Based on customer needs, in the beginning of product development, offer a solution, products design, by structural component designed to casting parts, optimize product design, reduce costs and creating more value for customers.

Use casting simulation analysis system software, try our best to ensure the success of one-time trial sample. We have special technology and skill to solve and handle special material, special structure, special defect and special processing.

Our comparative advantages

(1) Competitive price, all products are casted and machined in our factory, shipped directly to customer.

(2) Reliable quality, IATF16946 certified casting manufacturer, we have strict control about quality.

(3) Professional, we focus on production of Auto Parts for more than ten years.

(4) Fast shipment, we have a efficient management system, several automatic casting lines, and more than ten machining lines.

(5) Excellent service, our sales team has more than ten years' experience in oversea market, we know you better.

(6) Flexible production, we can customize the product according to your drawing.

FAQ

1.What advantages do you have than other suppliers?

a). Stamping, Machining, Welding, Die casting and Surface treatment equipment are equipped for providing you our best service and solutions.

b). 40 years of experience.

c). On-time delivery.

d). Strict Quality Control System: 100% inspection before the shipment.

2.What are the production capacity of your company?

a). In Merid, fabrication works include precision stamping, deep drawing, fine blanking, cnc punching, cnc bending, laser cutting, flame cutting, cnc milling, cnc turning, tube bending, aluminum extruding, welding,die casting, etc.

b). Metal materials include stainless steel, iron, carbon steel, spring steel, aluminum, titanium, copper, brass, bronze etc.

3.What equipments do you own?

a). Punch Press: 16T-500T.

b). Welding: Carbon dioxide welding, spot welding, tig welding, automated robotic welding.

c). Machining: CNC lathe and machine centers, light machines(drilling, milling and tapping).

d). Die casting: 80T-500T.

e). Surface treatment: Shot blasting facility, Polishing, Deburring.

4.What finish can you make?

We could make finish such as powder coating, painting, galvanizing, baked enamel, anodizing finish, and other plating finishes etc.

5.How can you guarantee the quality?

Quality control department build the control plan before starting the project, the strict inspection will be applied throughout the whole production.