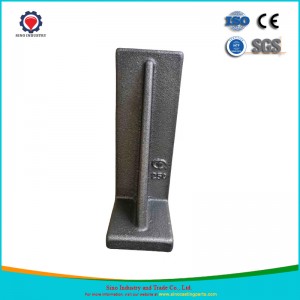

Casting/Foring/Machining Mechanical Parts for Mining/Construction/Agricultural Machinery

Basic Info.

Molding R&D, Casting, Machining, Surface Treatment, Inspection, Packing & Loading, Aftersale service etc.

| Application | Heavy truck parts/ Light Truck parts/ Valve / Pump / Agriculture Machinery / Elevator Part / Construction Tools / Printing Press Equipment / Auto Parts / Fireflghting Equipment /etc |

| Process | Mold Macking, Casting, Machining, Surface treatment, Inspection, Packing, Loading |

| Materials | Grey cast iron, Ductile cast iron, Carbon steel, Stainless steel, etc |

| Casting technical | Clay dry sand casting / resin sand casting / precision casting / investment casting / lost wax casting / shell-mould / silica sol casting / water glass casting |

| Casting blank size | 2mm-1500mm / according to customer's requirement |

| Casting blank weight | 0.01kg-3000kg |

| Casting tolerance | CT5-CT8 |

| Machining tolerance | 0.01mm |

| Machining | Lathing / Milling / Turning / Boring / Drillig / Tapping / Grinding / etc |

| Surface qulity | Ra0.8-Ra3.2 / according to customer requirement |

| Surface treatment | Shot blasting / Polishing / Painting / Powder coating / Anodizing / Zinc plating / Nickel plating / blacking / etc |

| Quality control | 100% inspection berore shipment |

| Design/File/formats | 3D, Auto CAD (IGS,DXF,DXF,DWG,STP, STEP,STL,X-T) / Soild Works / Unigraphics / PDF /etc |

| Certification | ISO9001:2008 |

| Package | Bubble plastic bag / polybag / pallet / wooden case etc |

| Sample | Available |

| OEM service | Available |

Our Advantages

(1). Competitive price, all products are casted and machined in our factory, shipped directly to customer.

(2). Reliable quality, ISO9001 and IATF16946 certified casting manufacturer, we have strict control about quality.

(3). Professional, we focus on production of heavy duty truck & trailer wheel hub and brake drum for more than 40 years.

(4). Fast shipment, we have a efficient management system, several automatic casting lines, and more than ten machining lines.

(5). Excellent service, our sales team has more than ten years' experience in oversea market, we know you better.

(6). Flexible production, we can customize the product according to your drawing.

Introduction of casting process

Our casting process is the iron based precoated sand casting and shell mold sand casting, with this method, a smooth casting surface can be achived For the iron based precoated sand casting, The inner quality is better because of the shock chill of the iron mold.

There are other types of casting method in different foundries, such as low wax casting, precision silican casting, lost foam casting, vaccum casting, resin sand casting, green sand casting, clay sand casting.centrifugal casting. powder casting, die casting. Different method require different moulding sand, and casting surface and inner quality is different according to different moulding sand.

According the material, there are grey iron sand casting, ductile iron sand casting, stainless steel casting, carbon steel casting, high Mn steel casting, bronze casting, aluminum casting.

Different size ,weight, quantity and material of the castings should use differrent casting method. Small size and weight stainless steel casting should use the precision silican casting or lost wax casting to get good dimension and outlooking. Big part and small quantity can choose green sand casting and clay sand casting, the cost will be lower. For batch quantity and small size aluminum can use die casting, fast, good looking and good quality.

Contact us for more information, we are professional and can customize your requirment according to your drawing, and we have experienced engineers to analyse your drawing and give you best soltuion.

About us

Established in 1980, Sino Industry and Trade Co., Ltd. (hereinafter referred to “SITC”) is a leading foundry manufacturer specializing in the design, research, development, manufacture and marketing in the foundry industry in China. Being one of major suppliers of customized parts for automobile/machinery manufacturers spreaded all over the world, as well as China automotive giants FAW/FOTON/SINOTRUK/SANY/HOWO/SHACMAN designated supplier for customization of auto parts, the company has been commited to offer high quality products with competitive prices and excellent service worldwide, and focuses on creating greater value for customers.

Headquartered in Rizhao City, Shandong Province, P.R. China, the company wholly owns a subsidiary production factory named “Rizhao Longshan Pricision Machinery Manufacture Co., Ltd.”, which possesses superior production equipment, strict and effective quality assurance system, excellent and perfect detection means, rich and abundant technical force. As an experienced, reliable, professional OEM/ODM manufacturer with good reputation in the industry which has already passed ISO9001&IATF16949 International Quality Management System certafication, SITC has a senior engineering technical team with special skills and rich experience for over 40 years in product design, casting, forging, and machining fields, which has special technology and skill to solve and handle special material, special structure, special defect and special processing.

The company not only possesses advanced equipment, but also gethers excellent professional technicians and skilled operators. More than 40 years experience in casting/forging/machining industry, with 60 experienced technical engineers and 800 skilled workers, the company’s goal is to leverage its first-mover advantage in this field to support global low-carbon economic development. We are agile and quick to react to market dynamics, meet the evolving needs of, and provide optimal solution and real one-stop service to, our customers. Its only one and a half hours’ drive from our factory to the nearest shipping port(Qingdao Port)--which makes our delivery system more efficient.

We adhere to the principle of "customer first, integrity first, excellent products", strictly control quality and meet customer needs. We look forward to becoming your reliable business partner----your machinery parts production base, and a strong backing for competitiveness.

1. Business type: manufacturer with foundry and machining shop

2 Products: OEM/ODM casting&machining service

3. Factory size: covers more than 600,000 square meters,

4. Number of employees: 800+ employee

5. Year established: since 1980

6. Production capacity: 110,000T/Year

7. Certification: ISO9001 and IATF16949, SGS.

8. Customers: Auto manufacturer, truck and semi tractor manufactuer, and other machinery parts

9. Casting method: Iron/steel based precoated sand casting and precoated shell casting.

Main casting products and application

Machine accessory, machinery accessory, industry accessory, precision accessory, high performance accessory, device accessory, facility accessory, engine accessory, motor accessory, valve body, valve shell, valve casing, valve housing, gate valve, ball valve, connector, solenoid valve, pipe fittings, control valve, floating ball valve, pneumatic valve, industrial valve, gas valve, flange gate valve, directional valve, hydraulic control valve, butterfly valve, gearbox, gearbox accessory, gearbox body, gearbox shell, gearbox casing, gearbox housing, oil cylinder, water pump, impeller, pump impeller, stainless steel pump, centrifugal pump, slurry pump, sewage pump, electric pump, submersible pump, high pressure pump, chemical pump, pressure pump, water pump set, self-priming pump, garden pump, deep well pump, oil pump, fountain pump, pond pump, mud pump, single suction pump, fuel pump, hydraulic pump, hydraulic pump accessory, hydraulic spare accessory, pump spare accessory, water pump accessory, diesel pump, vacuum pump, pump accessory, pump body, pump shell, pump housing, pump casing, pump cover, auto pump, car pump, automotive pump, automobile pump, vehicle pump, truck pump, lorry pump, farm machinery accessory, farm machine accessory, farm vehicle accessory, farm truck accessory, agricultural machinery accessory, agriculture machinery accessory, agricultural machine accessory, agriculture machine accessory, agricultural vehicle accessory, agriculture vehicle accessory, agricultural truck accessory, agriculture truck accessory, combine harvester accessory, mining machinery accessory, mining machine accessory, mining truck accessory, mining vehicle accessory, mining equipment accessory, machine spare accessory, hardware accessory, marine hardware, petrochemical accessory, petrochemical machine accessory, petrochemical machinery accessory, petrochemical equipment accessory, petrochemical device accessory, petrochemical facility accessory, petrochemical installation accessory, petroleum accessory, petroleum machine accessory, petroleum machinery accessory, petroleum equipment accessory, petroleum device accessory, petroleum facility accessory, petroleum installation accessory, energy accessory, energy machine accessory, energy machinery accessory, energy equipment accessory, energy device accessory, energy facility accessory, energy installation accessory, power machine accessory, power machinery accessory, power equipment accessory, power device accessory, power facility accessory, power installation accessory, power plant accessory, power plant machine accessory, power plant machinery accessory, power plant equipment accessory, power plant device accessory, power plant facility accessory, power plant installation accessory, shipbuilding accessory, shipbuilding machine accessory, shipbuilding machinery accessory, shipbuilding equipment accessory, shipbuilding device accessory, shipbuilding facility accessory, shipbuilding installation accessory, engineering accessory, engineering machine accessory, engineering machinery accessory, engineering equipment accessory, engineering device accessory, engineering facility accessory, engineering installation accessory,high quality accessory, diesel engine, cast iron, iron casting, cast iron accessory, casting accessory, sand casting accessory, sand casting accessory, sand casting accessory, cast steel, steel casting, cast steel accessory, etc.

FAQ

1.Q:Are a you trading company or manufacturer?

A: We are a IATF16949 and ISO9001 certified factory specilizing in casting&machining industry for more than 40 years.

2.Q: what is the lead time?

A:Generally it is 30-45 days for mass production with custom service.

3.Q:Do you provide samples?ls it free or extra?

A: Yes we provide samples,for sample charge as per sample condition to decide free or charged,usually for not too much time used consumed machining process are free.

4.Q:What is your terms of payment?

30% T/T in advance, balance before shipment. or as per negotiation.

5.Q: Can we know the production process without visiting your factory?

A:We will offer detailed production schedule and send weekly reports with digital pictures and videos which show the casting&machining progress.

6.Q:Available for customized design drawings?

A:Yes, DWG.DXF.DXWIGES.STEP.PDF etc.

7.Q: Will my drawing be safe after you get it?

A: Yes, we will not release your design to third party unless with your written permission. We can sign the NDA before your send us the drawings.

8.Q:How do you guarantee the quality ?

A:(1)Checking the raw material after they reach our factory--.---

Incoming quality control(IQC)

(2) Checking the details before the production line operated

(3) Have a full inspection and routing inspection during mass production---

In-process quality control(IPQC).

(4) Checking the goods after they are finished---- Final quality control(FQC)

(5) Checking the goods after they are finished-----Outgoing quality control(QC)

(6)100% inspection and delivery before shipment

9.Q: Can you customize my products?

A: Yes, we can customize products with your design drawings like DWG, DXF, DXW, IGES, STEP, PDF, etc.

10.What type of file format can you accept?

PDF, IGS, DWG, STEP, MAX

11.What is your surface treatment?

Including: powder coating, sand blasting, painting, polishing, acid pickling, anodizing, enamel, zinc plating, hot-dip galvanizing, electrophoresis, chrome plating.