Custom Casting Parts with CNC Machining for Train/Locomotive by Professional Manufacturer

Product Details

| Item | Train/Locomotive Parts |

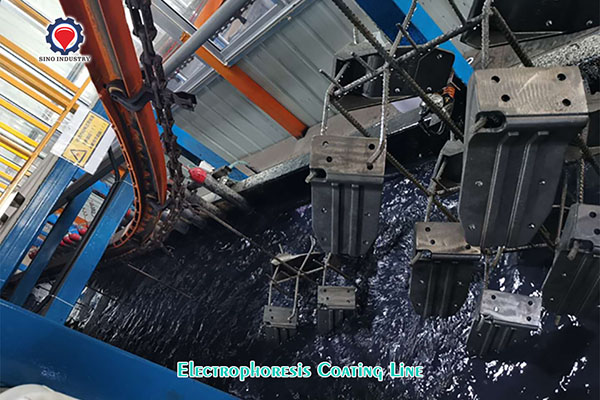

| Surface Preparation | Sand Blasting, Plating, Galvanized, Spray-Paint, Passivating, Polishing, Electrophoresis, Machining, etc. |

| Surface Treatment | Shot Blasting, Polishing, Painting, Powder Coating, Anodizing, Zinc Plating, Nickel Plating, Blacking, etc. |

| Surface Roughness | Ra0.05∼Ra50, Depends on Customer’s Requirements |

| Heat Treatment | Normalizing, Annealing, Quenching, Tempering, etc. |

| Process | Mold Making, Casting, Machining, Surface treatment, Inspection, Packing, Loading |

| Casting Tolerance | CT5-CT8 |

| Casting Blank Size | 2mm-1500mm or According to Customer's Requirement |

| Casting Blank Weight | 0.01kg-3000kg |

| Coating | Electrophoresis Coating |

| Machining | Lathing, Milling, Turning, Boring, Drillig, Tapping, Grinding, etc |

| Machining Tolerance | 0.01mm |

| Design Software/ Formats | 3D, Auto CAD (IGS,DXF,DXF,DWG,STP, STEP,STL,X-T)/Soild Works, CAXA, Rhino, CATIA, SIMIO, ALIAS, ARENA, Unigraphics |

| Certification | ISO9001:2015, CE, SGS, RoHS, IATF16949 |

| Inspection Equipment | Test Equipment: Spectrum Analyzer, Hexagon CMM, Hardness Test Equipment, Tension Test Machine, E-Coating Testing Equipments, Metalloscope. |

| Dimension Inspection | Coordinate Measuring Machine (CMM), Calipers, Height Gauge, Micrometer Calipers, Inside Caliper Gauge, Angle And R Gauge, Customized Gauge, etc. |

| Application | Train/Locomotive, Railway |

| Package | Bubble Plastic Bag, Polybag, Pallet, Wooden Case |

| Trademark | OEM |

| Origin | China |

| Loading Port | Qingdao Port |

| Annual Supply | 1000000 Pieces |

| Sample | Available |

| Sample Production Cycle | 30-45 Working days. |

| OEM/ODM Service | Available |

Product Parameter

Repeat positioning accuracy: ±1 second

Indexing positioning accuracy: ±2 seconds

Tooth contact rate: 100%

Tooth contact area: more than 85%

Shape and position accuracy: 0.005mm

Precision coupling shafts in aviation and aerospace engines, gas turbines, turbine compressors, rail transit, nuclear pumps and other fields can also be used in precision machine tool towers, equal turntables, universal milling and other intermittent indexing and positioning fields.

Technical strength

1. Independently complete the design and production of 3 types of tooth;

2. Master high precision grinding skills;

3. Capable of designing fixture, grinding wheel cutter.;

4. Capable of processing 2 teeth to 1440 teeth;

5. Maximum 2200mm machining diameter, and maximum 4000mm machining length of the end gear.

Product Description

1. High positioning accuracy, self-definable center;

2. Arc hyperboloid, larger contact area, high strength of tooth surface and tooth root, conducive to transfer large torque;

3. Arc teeth of high rigidity, can adapt to high load, heavy cutting applications;

4. Special concave and convex arc, meshing can overcome centrifugal force, and can prevent unilateral instantaneous vibration or warping, so as to achieve high-speed rotation;

5. Long service life, the contact area of arc teeth will not deteriorate due to long service time, but the more runnin, the better the contact surface;

6. Can split the complex workpiece processing, can effectively reduce the weight of the product, easy to design, manufacture, installation and maintenance of the product, and can effectively reduce the cost.

Products, Customization and OEM/ODM Service

Being one of major suppliers of customized parts for automobile/machinery manufacturers spreaded all over the world, as well as China automotive giants FAW/ FOTON/ SINOTRUK/ SANY/ HOWO/ SHACMAN designated supplier for customization of auto parts, we, Sino Industry and Trade Co., Ltd., has been commited to offer high quality products with competitive prices and excellent service worldwide, and focuses on creating greater value for customers.

The company wholly owns a subsidiary production factory named “Rizhao Longshan Pricision Machinery Manufacture Co., Ltd.”, which possesses superior production equipment, strict and effective quality assurance system, excellent and perfect detection means, rich and abundant technical force. More than 40 years experience in casting/machining industry, with 60 experienced technical engineers and 800 skilled workers. We have passed the “ISO 9001” and “ IATF 16949” International Quality Management System Certification.

As a professional OEM/ODM manufacturer, Our factory provides real one-stop service and optimal solution on customization for customers. Our main customized casting/forging/machining products related to train&railway are as follows:

Train parts/ components/ accessory, locomotive parts/ components/ accessory, railway parts/ components/ accessory, railroad parts/ components/ accessory, railway wheels, wheelset, train spare parts, hardware parts, facility parts/ components/ accessory, carbon steel parts/ components/ accessory, alloy steel parts/ components/ accessory, ductile iron parts/ components/ accessory, grey/ gray iron parts/ components/ accessory, train/ railway track, joint bar, fastener system, rail fastening system, angle bar, railway tie plate, railing base plate, railway fastener system, railway shoulders, forging rail anchor, railway anchor, subway parts/ components/ accessory, railway precise machining, railway wheel hub, railroad spring, railway coupler, victaulic, transportation parts, railway wagon, railway side frame, railway axle, train axle, railway bolster, wagon bogie, railway wheel, bogie car, railway bogie, locomotive wheelsets, locomotive spring, railway wagon parts/components/accessory, etc.

FAQ

1: Are you a genuine manufacturer?

Yes, all products showed in our website are produced in our certified factory; We are also a company registered by China Customs with the right to export and import.

2: I want to keep our design in confidence; can we sign NDA?

We are committed to protect customers’ privacy at all time. It is our obligatory responsibility to sign the NDA at customer’s request.

3: What should I inquiry to get your quotation?

Please offer us your detailed information for the product, such as drawings with 2D/3D by software Pro/E, Auto CAD, SolidWorks, UG etc; as well as materials, surface treatment, quantity, package. Any special requirements should be highlighted especially for tolerance.

4: How long is the manufacturing lead time?

Mass Production:30-45 working days after sample approval by your side.The lead time is the general production period without the transportation duration.

We could make some special production arrangement effectively if customer has urgent need.

In terms of the lead tiem, we possesses geographical superiority-its only one and a half hours’ drive from our factory to the nearest shipping port-which makes our delivery system more efficient.

5: How long does it take to ship goods from China by sea?

It takes about 5 weeks to European ports plus 1 week customs clearance, so you can get the container within 6 to 7 weeks. It takes about 2 weeks to east coast and 3 weeks to west coast US ports. The port of loading&departure will be Qingdao Port.

6: How long does it take to ship goods from China by air?

It takes about 7 days to all major destinations.

7: What are the payment terms?

Payment terms are negotiable and will improve for long term customers. During the initial stages, we request 50% of tooling fee in advance with the balance payable on acceptance of samples. Production orders can be negotiable. We prefer 30% deposit and the balance by T/T before cargo vessel’s departure.

8: New product development process?

Got tooling order and sample order with 50% deposit---Hold a meeting with the relation dept.To ensure the developing schedule---Design mould, fixture and gauge and making them in our factory---mould.fixture and gauge making---producing samples---approved from customer-purchasing material-forging-heat treatment-shot blasting-machining-Inspection-package---delievery.

9: How to handle the complains?

If happen any complaints after delivery, please just show us photos and detail compliants points, we will check with the production department and QC department immediately and give you best solving solution which agreed by both of us.