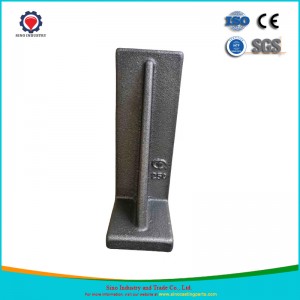

Customized High Precision Machine Parts by China ISO Manufacturer

Basic Info.

| Item | Machine Parts |

| Surface Preparation | Sand Blasting, Plating, Galvanized, Spray-Paint, Passivating, Polishing, Electrophoresis, Machining, etc. |

| Surface Treatment | Shot blasting/Polishing/Painting/Powder coating/Anodizing/Zinc plating/Nickel plating/blacking, etc. |

| Surface Roughness | Ra0.05∼Ra50, depends on Customer’s Requirements |

| Process | Mold Making, Casting, Machining, Surface treatment, Inspection, Packing, Loading |

| Casting tolerance | CT5-CT8 |

| Casting blank size | 2mm-1500mm or according to customer's requirement |

| Casting blank weight | 0.01kg-3000kg |

| Coating | Electrophoresis Coating |

| Machining | Lathing/Milling/Turning/Boring/Drillig/Tapping/Grinding, etc |

| Machining tolerance | 0.01mm |

| Design software/ formats | 3D, Auto CAD (IGS,DXF,DXF,DWG,STP, STEP,STL,X-T)/Soild Works/CAXA/Rhino/CATIA/SIMIO/ALIAS/ARENA/Unigraphics, etc |

| Certification | ISO9001:2015, CE, SGS, RoHS, IATF16949 |

| Inspection Equipment | Test equipment: Spectrum Analyzer, Hexagon CMM, Hardness test equipment, Tension test machine, E-coating testing equipments, Metalloscope. |

| Application | Construction Machinery/Truck/Vehicle, Farm Vehicle/Machinery/Truck, Agriculture Machinery/Truck/Vehicle, Mining Machinery, Marine Hardware, Train, Railway, Petroleum Machinery, Engineering Machinery, Shipbuilding, Power Equipment, etc. |

| Package | Bubble plastic bag/polybag/pallet/wooden case, etc. |

| Trademark | OEM |

| Origin | China |

| Loading Port | Qingdao Port |

| OEM/ODM service | Available |

Product description

1. Material:

Stainless steel:SS201,SS301,SS303,SS304,SS316,SS416 etc.

Iron:A36,45#,1213,12L14,1215 etc.

Aluminun:AL6061,AL6063,AL6082,AL7075,AL5052 etc.

Copper:C11000,C12000,C36000 etc.

Brass:HPb63,HPb62,HPb61,HPb59,H59,H62,H68,H80 etc.

Steel:mild steel,carbon steel,4140,4340,Q235,Q345B,20#,45# etc.

Plastic:ABS,PP,PEI,Peek,PE,POM,Delrin,Nylon,Teflon etc.

2. Parameter

3/4/5-axis CNCmilling,CNC Turning,dilling etc.

Precision:CNC turning ±0.003mm,CNC Milling ±0.01mm

Test equipment:Project,CMM,Altimeter,Micrometer,Thread Gages,Calipers,Pin Gauge etc.

Drawing Format:IGS,STP,X-T,DXF,Pro/E,PDFA

Workable size: CNC turning :φ0.5-φ300*750mm,

CNC Milling:510*1020*500mm(max).

3. Finishing

Chrome plating,Nickle plating,Tin plating,Zinc plating,Polishing,Anodizing,Power-coating,Oxide black.electroless nickel etc.

4. Ductile Iron Castings:

Molding process: Resin sand/Green Sand

Material: EN-GJS-400-15/EN-GJS-500-7/EN-GJS-600-3/EN-GJS-700-2

Molding: Hand molding/Molding machine Z145/146/148/Molding line.

Possible Heat Treatment: Annealing

Industry involved: Municipal Construction / Fluid/Automotive

Part unit weight range: 0.5kg-2000kgs

Max/Min wall thickness requirements: 4mm-250mm

5. Grey iron castings:

1) Molding process: Green sand/Resin sand

2) Material: EN-GJL-150/DIN 1691 GG-15, EN-GJL-200/DIN 1691-GG20, EN-GJL-250/DIN1691-GG25, EN-GJL-300/DIN1691-GG30

3) Molding: Hand molding/ Molding machine Z145/146/148/Molding line.

4) Industry involved: Municipal industry/Construction Fluid industry/Automotive industry

5) Part unit weight range: 0.5kg-2000kgs

6) Max/Min wall thickness requirements: 4mm

6. OEM&ODM Service

We are professional OEM/ODM casting/machining factory, as well as “ISO9001” and “IATF16949” certified foundry. Superior production equipment, strict and effective quality assurance system, excellent and perfect detection means, rich technical force. More than 40 years experience in casting/machining industry, with 60 experienced technical engineers and 800 skilled workers. We are gile and quick to react to customers’ requirements, meet the evolving needs of, and provide optimal solution to, our customers. A senior engineering technical team with special skills and rich experience for over 40 years in product design, casting, forging and machining fields. Advanced testing equipments, strict quality control system, to ensure us constantly, stably to provide high-quality products for customers.

Main equipments:Machining Center,CNC,Lathe,Turning machine,Milling machine,Drilling machine,Internal and external grinding machine,Cylindrical grinding machine,Tapping drilling machine,Wire cutting machine etc.

7. Delivery

30-45days after the confirmation of sample(according to order quatity.) for mass production. The mode of transportation: Express,by sea or by air(according to customer needs)

Packaging: carton/wooden box/other

Its only one and a half hours’ drive from our factory to the nearest shipping port-which makes our delivery system more efficient.

8. Surface Treatment

Heat Treatment, Painting, Power Coating, Black Oxide, Silver/Gold plating, Electrolytic Polishing, Nitrided, Phosphating, Nickel/Zinc/Chrome/TiCN Plated, Anodizing, Polishing, Passivation, Sandblasting, Galvanizing, Heating Treatment, Harden, Laser mark etc. as customer requested.

9. CNC Processing Ability

We have a large number of machines to meet Turning/Milling/Drilling/Stamping etc. different processing, such as CNC machining center 3-Axis, 4-Axis and 5-Axis, CNC lathe machine, CNC automatic lathe machine, Punching machine, grinder, precision internal/external grinding, wire cutting, spark machine, etc. The detection equipment: projector, altimeter, digital micrometer, digital caliper, quick gauge, plug gauge, internal/displacement gauge and other high-precision testing instruments, the detection accuracy up to 0.001mm.

10. Drawings for customization

Products showed here are made to the requirements of specific customers and are illustrative of the types of manufacturing capabilities available. Please send us your detailed drawings/samples/requirements to enable us to offer you a formal quotation. Our policy is that none of these products will be sold to 3rd parties without written consent of the customers.

Main Products&Application

Mechanical Components, Large sized machinery components, Boat components and Marine hardware, Construction hardware, Auto components and accessories, Medical Instrument components, pump & valve components and accessories, Impellers and propellers, Pipe Fittings or pipeline accessories, Other industry metal casting components, machinery components, machine components, industrial components, industry components, equipment components, mechanical components, machining components, cnc machining components, cnc components, cnc milling components, turning components, precision components, high performance components, device components, facility components, engine components, motor components, precision machine components, valve components, valve body, valve shell, valve casing, valve housing, gate valve, ball valve, connector, solenoid valve, pipe fittings, control valve, floating ball valve, pneumatic valve, industrial valve, gas valve, flange gate valve, directional valve, hydraulic control valve, butterfly valve, gearbox, gearbox components, gearbox body, gearbox shell, gearbox casing, gearbox housing, oil cylinder, water pump, impeller, pump impeller, stainless steel pump, centrifugal pump, slurry pump, sewage pump, electric pump, submersible pump, high pressure pump, chemical pump, pressure pump, water pump set, self-priming pump, garden pump, deep well pump, oil pump, fountain pump, pond pump, mud pump, single suction pump, fuel pump, hydraulic pump, hydraulic pump components, hydraulic spare components, pump spare components, water pump components, diesel pump, vacuum pump, pump components, pump body, pump shell, pump housing, pump casing, pump cover, auto pump, car pump, automotive pump, automobile pump, vehicle pump, truck pump, lorry pump, farm machinery components, farm machine components, farm vehicle components, farm truck components, agricultural machinery components, agriculture machinery components, agricultural machine components, agriculture machine components, agricultural vehicle components, agriculture vehicle components, agricultural truck components, agriculture truck components, combine harvester components, mining machinery components, mining machine components, mining truck components, mining vehicle components, mining equipment components, machine spare components, hardware components, marine hardware, petrochemical components, petrochemical machine components, petrochemical machinery components, petrochemical equipment components, petrochemical device components, petrochemical facility components, petrochemical installation components, petroleum components, petroleum machine components, petroleum machinery components, petroleum equipment components, petroleum device components, petroleum facility components, petroleum installation components, energy components, energy machine components, energy machinery components, energy equipment components, energy device components, energy facility components, energy installation components, power machine components, power machinery components, power equipment components, power device components, power facility components, power installation components, power plant components, power plant machine components, power plant machinery components, power plant equipment components, power plant device components, power plant facility components, power plant installation components, shipbuilding components, shipbuilding machine components, shipbuilding machinery components, shipbuilding equipment components, shipbuilding device components, shipbuilding facility components, shipbuilding installation components, engineering components, engineering machine components, engineering machinery components, engineering equipment components, engineering device components, engineering facility components, engineering installation components, high quality components, diesel engine, cast iron, iron casting, cast iron components, casting components, sand casting components, cast steel, steel casting, cast steel components, sand casting, die casting, investment casting, lost wax casting, gravity casting, vaccum casting, etc.

Our Competitive Edges

1. A senior engineering technical team with special skills and rich experience for over 40 years in product design, casting, forging and machining fields.

2. Have special technology and skill to solve and handle special material, special structure, special defect and special processing.

3. Advanced testing equipments in the industry, and strict quality control system, to ensure us constantly, stably to provide high-quality products for customers.

4. Carrying out ISO9001 and IATF16949 quality management system, guarantee of the quality.

5. China automotive giants FAW/FOTON/SINOTRUK/SANY/HOWO/SHACMAN designated supplier for customization of auto parts.

6. Mature one-stop service system.

We provide real one-stop service for all customers

(1)we are the source manufacturers, and our price has an absolute advantage.

(2)We have our own technology department to solve all-round problems related to product technology.

(3)We have a complete production line, products from raw materials to finished products are under our control.

(4)We have a strict product quality monitoring system to ensure the quality of our products and after-sales service.

7. Wide application of products

The castings produced by us are widely used in various industries,such as construction vehicles, trains, railways, forklifts, agricultural machinery and other mechanical equipment. We can produce all kinds of castings with high precision CNC machining according to customer's drawings/sample/requirements.

FAQ

Q. Are you manufacturer or a trader?

A. We are an experienced, reliable, professional OEM/ODM manufacturer with good reputation in the casting/forging/machining industry, and a major supplier of casting/forging/machining parts for automobile/machinery manufacturers spreaded all over the world. Also we are one of Chinese automobile manufacturer giants FAW/FOTON/SINOTRUK/SANY/HOWO/SHACMAN designated suppliers for customized casting&machining parts. Headquartered in Rizhao City, Shandong Province, P.R. China, Sino Industry and Trade Company wholly owns a subsidiary production factory named “Rizhao Longshan Pricision Machinery Manufacture Co., Ltd.”, which possesses superior production equipment, strict and effective quality assurance system, excellent and perfect detection means, rich and abundant technical force.

Q. Where is your location?

A. We are located in Rizhao City, Shandong Province, P.R. China. Your are welcome to visit us anytime.

Q. How many years have you been in this business field?

A. For more than 40 years.

Q. What is your brand?

A. Longshan.

Q. Can you provide OEM/ODM service ?

A. We are professional OEM/ODM casting/machining factory, as well as “ISO9001” and “IATF16949” certified foundry. More than 40 years experience in casting/machining industry, with 60 experienced technical engineers and 800 skilled workers. A senior engineering technical team with special skills and rich experience for over 40 years in product design, casting, forging and machining fields. As a LEADER in the precision casting/forging/machining industry, we provide real one-stop service and optimal solution for customers. Based on customer needs, in the beginning of product development, offer a solution, products design, by structural component designed to casting parts, optimize product design, reduce costs and creating more value for customers.

Q. How do you ensure the quality?

A. We have strict QC process:

1) Before production, Check strictly the raw material quality.

2) During the half production, We check the finished product quality.

3) Before shipment, We test every product and check defects. Any products with defects won't be loaded.

More details, Please check with our sales team.

Q. What about your payment terms?

A. We can accept various terms, including T/T , L/C , Western Union, etc.

Q. what services can buyer get from you?

Accepted Delivery Terms: FOB,CFR,CIF,CIP,DDP,DDU;

Accepted Payment Currency :USD,EUR,CNY;

Language Spoken:English,Chinese.