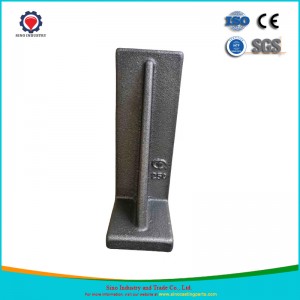

OEM Factory Custom Casting Steel/Iron/Metal for Machinery Parts with CNC Machining

Basic Info.

OEM Steel Casting Iron Sand Casting Aluminum Casting

| Item | OEM Steel Casting Iron Sand Casting Aluminum Casting Swing Check Valve |

| Material | Aluminum, iron, steel, etc. |

| Standard | DIN931,DIN933,DIN912,DIN125,DIN127,DIN934,DIN603 , SAE or GB |

| Process | Sand casting |

| Size | According to the drawings or customer's requirements |

| Casting parts weight | 0.01 to 3000KG, some aluminum sand casting parts can be several tons |

| Machining | CNC machining |

| surface treatment | Zine palting, Painting, Powder coating, or as customers' requirements |

| Application | Machinery, machining parts |

| Package | Usually is standard export packing with Plywood Case and also can upon customers' requirement |

| Delivery time | Tooling: roughly 30 days; Production: roughly 35 days |

| Shipping | By air, by express or by sea |

Product Description

DN700 Pn10 Double Flanged Swing Check Valve

Features:

1. Small in size, light in weight, compact in structure,easy in maintenance.

2. Two torsion springs are used excreting on each of the pair valve plates,which close the plates quickly and automatically.

3. The quick-close action prevents the medium from flowing back and eliminates water hammer effect.

4. Short body structure length and good rigidity.

5. This valve is tightly sealed, without leakage under the pressure water test.

6. Safe and reliable in operation,high interference-resistance.

Swing check valve a save-energy product, is manufactured based on the foreign advanced technology and in accordance with relative international standards. This product is featured by excellentretaining performance,high safety and reliability and low flow resistance. It is suitable for system in the industries of perochemical, food processing, medcine,textile, papermaking, water supply and drainage, metallurgy, energy and lighindustry etc used as a check valve in one way.

| Product Model | DH77X/H76W-16 |

| Nominal Diameter | DN40~700 |

| Nominal Pressure | PN1.0~1.6MPa |

| Suitable Medium | Water,oil,gas |

| Suitable Temperature | -23°C~121°C |

| Standard Flange connection | GB2555-81/BS5163/DIN3352/ASTM |

| Standard length of the structure | CVA250-88 |

| Pressure test standard | GB4981-85 |

Custom Service Aluminum Alloy /Zinc Pressure ADC12 Die Casting Parts

1, Aluminium die casting is a process of injection aluminum alloy under pressure, which produces parts in high volume at low costs.

2, There are two processes of Aluminum die casting: hot chamber and cold chamber.

3, A complete cycle can vary from one second for small components to minutes for a casting of large part, making aluminium die casting the fastest technique available for producing precise aluminium alloy parts.

4, We have a strong and highly efficient R&D team, which will design and make OEM/ODM products according to your drawings and samples.

5, Certification: IATF16949, ISO9001, SGS, ROHS

Aluminum Zinc die-casting products are characterized by high quality, light weight, high hardness and nice appearance.Therefore, aluminum die casting products are widely used in the automotive field. For example, Heat sink, Engine cooling fan, Water pump housing, end cover, air condition housing etc.

Production Processing

1. All parts produced according to your CAD and 3D drawings or samples. Please send the blueprint or drawing artwork first, upon which we will offer you a formal quotation.

2. Materials as below.

Aluminum, Stainless steel, 17-4pH, DERLIN, Ceramics, Carbamide alloy, PEEK etc

3. The surface finished include:

Hardness anodizing black/clear, steel oxidizing dark-blue, electro-polishing, electroless nickel plating, silver plating, golden plating etc.

4. OEM&ODM are welcomed.

5. Packing: Wooden cases, carton or on requirement.

6. Maine equipment:

Machining center, CNC, Lathe, Turning machine, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Tapping drilling machine, Wire cutting machine etc.

7. Testing facility: Coordinate measuring machine, projector, roughness tester, hardness tester, concentricity tester. Height tester, .

8. Part size: Diameter from 0.5mm to 150mm

9. Tolerance: +/-0.01mm

10, Lead time: 30-45days after the confirmation of sample

11: Minimum Order: Comply with customer's demand

12, Delivery way: EXPRESS, BY SEA OR BY AIR on your requirement.

Our company specialized in manufacturing and designing of various non-standard precision parts, our service cover mechanical engineering, electronic engineering, semiconductor, tele-communication, medical equipment, automation equipments etc. We invested advanced manufacturing equipments(such as high-speed CNC Machining Center, Grinding machines, Milling machines, CNC lathe, Stamping machine, Wire-Cutting machines)and quality testing machines(such as coordinate measurement machine, Micro-projector and Height Gauge etc. ) we can also provide one-stop shopping OEM.

All parts can be machined with tiny tolerance, precise dimensions and a smooth surface. Roughness typically considered to be the high frequency, short wavelength component of a measured surface.

It's our pleasure to serve you if we get your inquiry with detailed specification and drawings, we will submit our competitive offer ASAP and provide you premium quality porduct.

OEM/ODM Service Procedures

1, Drawings confirmed(General clients provide the drawing or samples)

2, Opening the Mold

3, Die Casting ( Aluminium or Aluminium Alloy)

4, Precision Machining (Burring, Lathe, Milling, etc)

5, Surface treatment: Polishing, Electroplating, Sandblasting, Anodizing

6, Inspection and Packing

7,Loading for shipment

Pre-sales Services

To acheieve the top combination of technology and sales services,so that users have a service experience in every purchase.

A.Communicate with customers about product technologu before purchasing and give suggetsions.

B.Provide professional drawings to avoid errors.

C.Design and produce products reasonably according to customer requirements.

On-sales Services

A. Compare price,quality and service to achieve the best cost performance.

B. Strict contract terms and careful attention to every small requirement of customers.

C. Keep communication with customers in the production process.The model,caliber,quantity,standard,color,valve label,casting and so on need to be confirmed again.

After-sales Services

A.Provide product certificates,inspection certificates,installation indtructions etc.,according to the contract.

B.The company will deal with the non-conformity of contract resuirements within 2 hours.

C.The warranty period for all valves is 12-18months from the date of acceptance.

D.If product quality problems occur under correct installation and use,our company will be responsible to the end.

E.Provide spare parts,debugging and maintenance services.

F.Any after-sales feedback will be resolved within 24 hours.

Why choose us?

1. Sino Industry and Trade Company wholly owns a subsidiary production factory named “Rizhao Longshan Pricision Machinery Manufacture Co., Ltd.”, which possesses superior production equipment, strict and effective quality assurance system, excellent and perfect detection means, rich and abundant technical force.

2. A professional manufacturer specializing in the design, development, manufacture and marketing in the foundry industry. We have our own technique personnel and sales team. A senior engineering technical team with special skills and rich experience for over 40 years in product design, casting, forging and machining fields.

3. Delivery on time. Its only one and a half hours’ drive from our factory to the nearest shipping port-which makes our delivery system more efficient.

4. “ISO9001” and “IATF16949” certified factory, Provide real one-stop service and optimal solution for customers.

5. A source manufacturer, our products have a considerable price advantage relative to intermediary traders, so you will get a Competitive price form us .

6. Chinese automobile manufacturer giants FAW/FOTON/SINOTRUK/SANY/HOWO/SHACMAN designated supplier for customized casting&machining parts.

7. More than 40 years experience in casting/machining industry, with 60 experienced technical engineers and 800 skilled workers.

8. A senior engineering technical team with special skills and rich experience for over 40 years in product design, casting, forging and machining fields.

9. Stick to the business management philosophy that "Starting from the customer needs and ending with their satisfaction". Focusing on customer demands and exceeding their expectations.

10. Professional OEM/ODM casting/machining factory.

11. “ISO9001” and “IATF16949” certified factory.

Sand casting

Our factory has large-scale casting equipment of 50 sets, we have different technology with different type of sand kind and parts shape. The largest casting we can cast is 15 tons. Our yearly capacity for sand casting is about 2000 tons for cast steel and 30000 tons for cast iron.

Our factory has more than 30 kinds, 400 sets in total, including 60 sets of four/five-axis machining center (CNC) and 2 sets of digital special machines designed with double main axle boxes, of mechanical equipments related to casting, forging, stamping, punching, molding, machining, processing and surface treatment. Our annual capacity for sand casting is around 30000 tons for steel casting and 80000 tons for iron casting.

Products Range

Mechanical Accessory, Large sized machinery accessory, Boat accessory and Marine hardware, Construction hardware, Auto accessory and accessories, Medical Instrument accessory, pump & valve accessory and accessories, Impellers and propellers, Pipe Fittings or pipeline accessories, Other industry metal casting accessory, machinery accessory, machine accessory, industrial accessory, industry accessory, equipment accessory, mechanical accessory, machining accessory, cnc machining accessory, cnc accessory, cnc milling accessory, turning accessory, precision accessory, high performance accessory, device accessory, facility accessory, engine accessory, motor accessory, precision machine accessory, valve accessory, valve body, valve shell, valve casing, valve housing, gate valve, ball valve, connector, solenoid valve, pipe fittings, control valve, floating ball valve, pneumatic valve, industrial valve, gas valve, flange gate valve, directional valve, hydraulic control valve, butterfly valve, gearbox, gearbox accessory, gearbox body, gearbox shell, gearbox casing, gearbox housing, oil cylinder, water pump, impeller, pump impeller, stainless steel pump, centrifugal pump, slurry pump, sewage pump, electric pump, submersible pump, high pressure pump, chemical pump, pressure pump, water pump set, self-priming pump, garden pump, deep well pump, oil pump, fountain pump, pond pump, mud pump, single suction pump, fuel pump, hydraulic pump, hydraulic pump accessory, hydraulic spare accessory, pump spare accessory, water pump accessory, diesel pump, vacuum pump, pump accessory, pump body, pump shell, pump housing, pump casing, pump cover, auto pump, car pump, automotive pump, automobile pump, vehicle pump, truck pump, lorry pump, farm machinery accessory, farm machine accessory, farm vehicle accessory, farm truck accessory, agricultural machinery accessory, agriculture machinery accessory, agricultural machine accessory, agriculture machine accessory, agricultural vehicle accessory, agriculture vehicle accessory, agricultural truck accessory, agriculture truck accessory, combine harvester accessory, mining machinery accessory, mining machine accessory, mining truck accessory, mining vehicle accessory, mining equipment accessory, machine spare accessory, hardware accessory, marine hardware, petrochemical accessory, petrochemical machine accessory, petrochemical machinery accessory, petrochemical equipment accessory, petrochemical device accessory, petrochemical facility accessory, petrochemical installation accessory, petroleum accessory, petroleum machine accessory, petroleum machinery accessory, petroleum equipment accessory, petroleum device accessory, petroleum facility accessory, petroleum installation accessory, energy accessory, energy machine accessory, energy machinery accessory, energy equipment accessory, energy device accessory, energy facility accessory, energy installation accessory, power machine accessory, power machinery accessory, power equipment accessory, power device accessory, power facility accessory, power installation accessory, power plant accessory, power plant machine accessory, power plant machinery accessory, power plant equipment accessory, power plant device accessory, power plant facility accessory, power plant installation accessory, shipbuilding accessory, shipbuilding machine accessory, shipbuilding machinery accessory, shipbuilding equipment accessory, shipbuilding device accessory, shipbuilding facility accessory, shipbuilding installation accessory, engineering accessory, engineering machine accessory, engineering machinery accessory, engineering equipment accessory, engineering device accessory, engineering facility accessory, engineering installation accessory, high quality accessory, diesel engine, cast iron, iron casting, cast iron accessory, casting accessory, sand casting accessory, cast steel, steel casting, cast steel accessory, sand casting, die casting, investment casting, lost wax casting, gravity casting, vaccum casting, etc.

FAQ

1.Are you a factory or trading company? Do you have an advantage on price?

First of all, we are a casting manufacturer. We provide real one-stop service. The products purchased by customers are directly produced by our factory. Therefore, the price of our products has been reduced by 5% to 10% of the trade cost. Our price is absolutely superior.

2.How can you guarantee delivery on time.

Before each new order, each department will hold a meeting to make a strict production plan, implement the supply of raw materials, distribution of production plan and other matters. In addition, the cooperation between us and large companies has also promoted the improvement of our delivery system.

3.How do you guarantee the quality of your products?

First of all, we will carry out quality inspection on the raw materials of the products and ensure that they are qualified. Then we will carry out necessary test and inspection during the production of the products.

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have a full inspection and routing inspection during mass production---In-process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

4.How can we quote for you?

Please send us enquiry by email, with all the technical drawings you have. Such as material grade, tolerance, machining demands, surface treatment, heat reatment, mechanical property requirements, etc. Our specialized engineer will check and quote for you, we would appreciate the opportunity and will respond in 3-5 working days or less.

5. Which industries do the purchased products apply to?

We are a professional OEM manufacturer. Our products are widely used in forklift, truck, train ,machinery, mining, construction, food and other industries. As long as there is a demand for spare parts, we can process it for production.