Factory Price Train Parts Customized by China Professional OEM Manufacturer

Product Details

| Item | Train/Railway Parts |

| Surface Preparation | Sand Blasting, Plating, Galvanized, Spray-Paint, Passivating, Polishing, Electrophoresis, Machining, etc. |

| Process | Mold Making, Casting, Machining, Surface treatment, Inspection, Packing, Loading |

| Casting Tolerance | CT5-CT8 |

| Casting Blank Size | 2mm-1500mm or According to Customer's Requirement |

| Casting Blank Weight | 0.01kg-3000kg |

| Coating | Electrophoresis Coating |

| Machining | Lathing, Milling, Turning, Boring, Drillig, Tapping, Grinding, etc |

| Machining Tolerance | 0.01mm |

| Design Software/ Formats | 3D, Auto CAD (IGS,DXF,DXF,DWG,STP, STEP,STL,X-T)/Soild Works, CAXA, Rhino, CATIA, SIMIO, ALIAS, ARENA, Unigraphics |

| Certification | ISO9001:2015, CE, SGS, RoHS, IATF16949 |

| Inspection Equipment | Test Equipment: Spectrum Analyzer, Hexagon CMM, Hardness Test Equipment, Tension Test Machine, E-Coating Testing Equipments, Metalloscope. |

| Application | Train, Railway |

| Package | Bubble Plastic Bag, Polybag, Pallet, Wooden Case |

| Trademark | OEM |

| Origin | China |

| Loading Port | Qingdao Port |

| Annual Supply | 1000000 Pieces |

| Sample | Available |

| Sample Production Cycle | 30-45 Working days. |

| OEM/ODM Service | Available |

Technical parameters

In order to give you a better understanding of the products, we have tabulated the product categories for your reference.

| NO. | DN mm | D Min-max mm | Size mm | |

| H | L | |||

| 1 | 13 × 5 | 22 ~ 24 | 51 ± 2 | 50 ± 1 |

| 2 | 19 × 6 | 30 ~ 33 | 63 ± 2 | 50 ± 1 |

| 3 | 25 × 5 | 34 ~ 36 | 63 ± 2 | 50 ± 1 |

| 4 | 25 × 6 | 36 ~ 39 | 63 ± 2 | 50 ± 1 |

| 5 | 25 × 8 | 40 ~ 43 | 50 ± 1 | |

| 6 | 32 × 5 | - | 50 ± 1 | |

| 7 | 32 × 6 | 43 ~ 46 | 76 +3/-2 | 50 ± 1 |

| 8 | 32 × 8 | 47 ~ 50 | 78 +3/-2 | 50 ± 1 |

| 9 | 38 × 5 | - | 50 ± 1 | |

| 10 | 38 × 6.5 | 50 ~ 52 | 83 +3/-2 | 50 ± 1 |

| 11 | 38 × 8 | 53 ~ 56 | 85 +3/-2 | 50 ± 1 |

| 12 | 40 × 7 | 53 ~ 56 | 85 +3/-2 | 50 ± 1 |

| 13 | 50 × 5 | - | ||

| 14 | 50 × 6 | 62 ~ 63 | ||

| 15 | 50 × 8 | 64 ~ 67 | 102 +3/-2 | 56 ± 1 |

| 16 | 50 × 10 | 69 ~ 71 | 106 +3/-2 | 56 ± 1 |

| 17 | 63 × 6 | - | ||

| 18 | 63 × 8 | 78 ~ 82 | 120 +4/-2 | 74 ± 1 |

| 19 | 75 × 7.5 | - | ||

| 20 | 75 × 8 | 89 ~ 94 | 132 +4/-2 | 76 ± 1 |

| 21 | 75 × 10 | 94 ~ 97 | 136 +4/-2 | 76 ± 1 |

| 22 | 80 × 8 | 94 ~ 97 | 137 +4/-2 | 76 ± 1 |

| 23 | 90 × 6.5 | - | ||

| 24 | 100 × 6.5 | - | ||

| 25 | 100 × 8 | 114 ~ 119 | 166 +4/-2 | 120 ± 1 |

| 26 | 100 × 10 | 118 ~ 122 | 170 +4/-2 | 120 ± 1 |

| 27 | 150 × 10 | 167 ~ 173 | 227 +4/-2 | 180 ± 1 |

| 28 | 150 × 10 | 167 ~ 173 | 227 +4/-2 | 180 ± 1 |

| 29 | 200X12 | 222 ~ 229 | 284 +4/-2 | 240 ± 2 |

Product Description

1. Product Application Fields

Train, locomotive, railway/railroad, high-speed rail, auto, car, truck, lorry, lorry truck, pickup truck, heave truck, heave-duty truck, light truck, commercial vehicle, forklift, vehicle, automobile, automotive, farm/agricultural/agriculture machinery/ machine/ truck/ vehicle, combine harvester, tractor, trailer, dump truck, mining equipment/machine/machinery/truck/vehicle, device, facility, industry/industrial parts, engine, construction machine/ machinery/ truck/ vehicle/ equipment, petrochemical, petroleum machine/machinery/equipment, energy, shipbuilding, general machinery, bus, passenger bus/car, coach bus, shuttle bus, tourist bus, sightseeing car, school bus, cargo trailer, special vehicle, trailer truck, dumper truck, marine hardware, petrochemical parts, petrochemical components, petrochemical accessory, petrochemical machine parts, petrochemical machine components, petrochemical machine accessory, petrochemical machinery parts, petrochemical machinery components, petrochemical machinery accessory, petrochemical equipment parts, petrochemical equipment components, petrochemical equipment accessory, petrochemical device parts, petrochemical device components, petrochemical device accessory, petrochemical facility parts, petrochemical facility components, petrochemical facility accessory, petrochemical installation parts, petrochemical installation components, petrochemical installation accessory, petroleum parts, petroleum components, petroleum accessory, petroleum machine parts, petroleum machine components, petroleum machine accessory, petroleum machinery parts, petroleum machinery components, petroleum machinery accessory, petroleum equipment parts, petroleum equipment components, petroleum equipment accessory, petroleum device parts, petroleum device components, petroleum device accessory, petroleum facility parts, petroleum facility components, petroleum facility accessory, petroleum installation parts, petroleum installation components, petroleum installation accessory, energy parts, energy components, energy accessory, eneryg machine parts, energy machine components, energy machine accessory, energy machinery parts, energy machinery components, energy machinery accessory, energy equipment parts, energy equipment components, energy equipment accessory, energy device parts, energy device component, energy device accessory, energy facility parts, energy facility components, energy facility accessory, energy installation parts, energy installation components, energy installation accessory, power machine parts, power machine components, power machine accessory, power machinery parts, power machinery components, power machinery accessory, power equipment parts, power equipment components, power equipment accessory, power device parts, power device components, power device accessory, power facility parts, power facility components, power facility accessory, power installation parts, power installation components, power installation accessory, power plant parts, power plant components, power plant accessory, power plant machine parts, power plant machine components, power plant machine accessory, power plant machinery parts, power plant machinery components, power plant machinery accessory, power plant equipment parts, power plant equipment components, power plant equipment accessory, power plant device parts, power plant device components, power plant device accessory, power plant facility parts, power plant facility components, power plant facility accessory, power plant installation parts, power plant installation components, power plant installation accessory, shipbuilding parts, shipbuilding components, shipbuilding accessory, shipbuilding machine parts, shipbuilding machine components, shipbuilding machine accessory, shipbuilding machinery parts, shipbuilding machinery components, shipbuilding equipment parts, shipbuilding equipment components, shipbuilding equipment accessory, shipbuilding device parts, shipbuilding device components, shipbuilding device accessory, shipbuilding facility parts, shipbuilding facility components, shipbuilding facility accessory, shipbuilding installation parts, shipbuilding installation components, shipbuilding installation accessory, engineering parts, engineering components, engineering accessory, engineering machine parts, engineering machine components, engineering machine accessory, engineering machinery parts, engineering machinery components, engineering machinery accessory, engineering equipment parts, engineering equipment components, engineering euiqpment accessory, engineering device parts, engineering device components, engineering device accessory, engineering facility parts, engineering facility components, engineering facility accessory, engineering installation parts, engineering installation components, engineering installation accessory.

2. OEM/ODM Service

All parts are custom made according to customer's drawings or samples. Technical drawings should specify the following factors:

Materials, structure, dimension, surface treatment, packaging

The comprehensive information will help us quickly calculate the accurate and reasonable price for you.

3. Research and Development

Design software and DEFORM Simulation Software-Pdf, auto CAD, solid works, UG, Pro/E, CAXA, proe, Rhino, Catia, Simio, Alias, Arena-were used by the R&D staffs during the design proess of new products 3D Solid Modeling.

CAD Software

4. Material

Ductile iron, grey/gray iron, stainless steel, Carbon Steel, Alloy Steel, Aluminum.

5. Heating Equipment

Electric Intermediate Frequency Furnace

6. Forging Equipment

2500Ton Double Disc Friction Press

1600Ton Double Disc Friction Press

1000Ton Double Disc Friction Press

630Ton Double Disc Friction Press

400Ton Double Disc Friction Press

Sawing Machine

Shot Blasting Machine

Air Hammer

Punch

7. Forging Weight Range:0.05kg-100kg

8. Heat Treatment Equipment

Electric heating furnaces with precise computerized

temperature control to achieve desired hardness and

mechanical properties.

Water/Oil/Polymer quenching pool with mechanical

Propeller agitation.

Induction/Flame hardening equipment.

9. Machining Equipment

CNC Center

CNC Milling Machine

CNC Drilling Machine

CNC Lathe

Grinding Machine

Wire Cutting Machine

Electric Pulse Machine

EDM

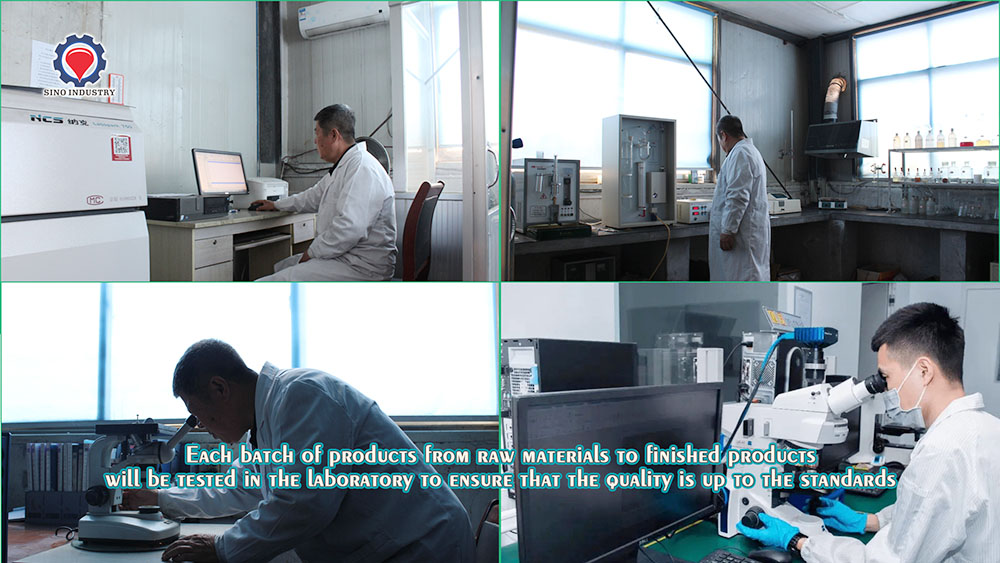

10.Inspection Equipment

Direct-Reading Spectrometer

Hydraulic Universal Testing Machine

Rockwell Hardness Tester

Brinell Hardness Tester

Vickers Hardness Tester

Metallographic Analyzer

Magnetic Particle Tester

Ultrasonic Tester

CMM

Spectral inspection machine

Tensile testing machine

FAQ

1. Are you a genuine foundry manufacturer or a trading company?

We are a genuine foundry manufacturer, a source manufacturer, we have a complete production line, all production links from raw materials to finished products are under our control. All products showed on our website are produced in our ISO9001:2015 certified factory; We are also a company registered by China Customs with the right to export and import.

2. I want to keep our design in confidence; can we sign NDA?

Sure, protecting customers' privacy information is our obligatory responsibility, signing a NDA would be reasonable for both parties.

3. What should I offer to get your quotation?

Please offer us your detailed information for the product, such as drawings with 2D/3D by software Pro/E, Auto CAD, SolidWorks, UG etc; as well as materials, surface treatment, quantity, package. Any special requirements should be highlighted especially for tolerance.

4. How long does it take to receive samples?

20 working days,the lead time is the general production period and does not include the transportation time. We can supply free samples with less quantity, but customers need to pay shipping cost.

5. How long is the manufacturing lead time?

Mass Production: 30-45 working days after sample approval by customer. The lead time is the general production period without the transportation duration.

We could make some special production arrangement effectively if customer has an urgent need.

6. How long does it take to ship goods from China by sea?

It takes about 5 weeks to European ports plus 1 week customs clearance, so you can get the container within 6 to 7 weeks.It takes about 2 weeks to east coast and 3 weeks to west coast US ports. All sea goods are shipped from Qingdao Port.

7. What are the payment terms?

Payment terms are negotiable and will improve for long term customers. During the initial stages, we prefer 30% deposit and the balance by T/T before sails.

8. New product development process?

Contract concluded---All departments gether to hold a meeting to formulate a developing schedule---Design mould, fixture and gauge and making them in our factory---mould fixture and gauge making---producing samples---approved from customer-purchasing raw materials-casting, forging-heat treatment-shot blasting-machining-spray painting/electrophoresis coating-Inspection-package---delievry.

9. Which countries do you export to?

Now mainly export to U.S.A, Germany, France, Italy, UK, Brazil, Swedish, Japan, Korea, Middle east of Asia, South East, Africa, and so on.

10. Can we pay a visit to your factory to conduct an audit?

Welcome and anytime.