High Performance Railway Parts Customized by One-Stop Service Manufacturer

Product Description

| Item | OEM Metal Forging Parts |

| Material | Carbon Steel, Alloy Steel, Cold and Hot Moulded Shell Steel, Stainless Steel, Heat-resistant Steel and Other High Alloy Steel Parts |

| Product Size | Available As Customer's Drawing Required |

| Color | Customer's Requirements |

| Mould | Design and produce by ourself |

| Drawing | Provide by customer or design according to the sample. |

| Drawing Format | Pro/E, AutoCAD, Solidworks, CAXA, UG, CAD, CAM, CAE, STP, IGES, etc. |

| Standard | ISO, DB34/T 1240-2010 etc. |

| Weight Range | 0.01-3000KG |

| Machining Precision | ±0.01mm |

| Surface Treatment | Trimming, Deburring, Polishing, Shot Blasting, Sand Blasting, Tumbling, Powder Coating, Anodizing, Passivation, Chemical Coating, Painting, Electroplating, Electrophoresis and so on. |

| Products Application | Automotive Industry, Bicycle and Motorcycle, Agricultural Machinery, Construction, Door/Windows and Furniture, Household Appliance, Beauty and Medical, Consumer Electronics, Smart Home, Robotics, Communications, Luggage, etc. |

| Production Diagram | Drawings or Samples>Mold Fabrication>Mold Test>Qualified Sample>Mass Production Die Casting>Deburring>Drilling&Tapping> Polishing>CNC Machining>Surface Treatment>Printing Logo>Quality Inspection>Packing>Shipping. |

Customized Casting/Machining Train/Railway Parts

Please note:

1.The case of die casting products is for reference only.

2.Our company supports customization, complete specifications, and factory direct sales.

3.The prices of all products showed here are for reference only, and the specific prices need to be negotiated by both parties according to the specific requirements of customers for die castings.

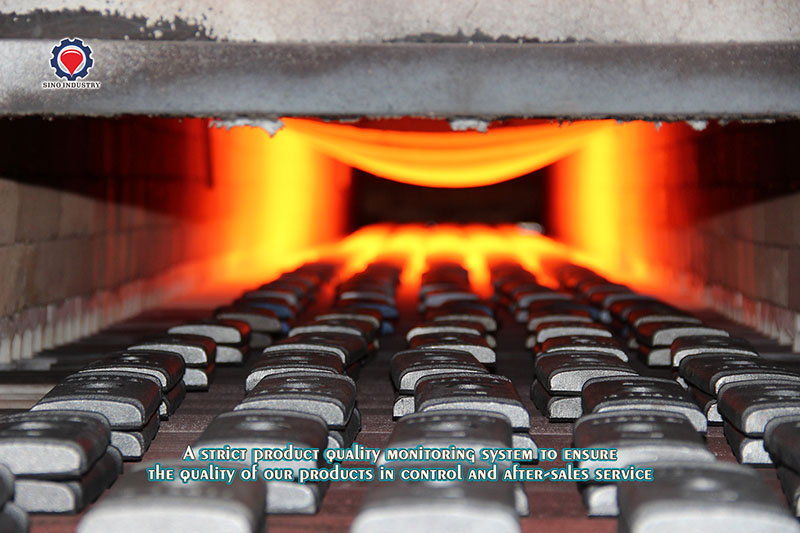

Casting process

Receiving drawings or samples---- quotation---trial mold production---mold making---mold design---sample confirmation---batch production---mass production

Applications of castings

Automobile, lighting, furniture, office equipment and household appliances, electronics, communication, machinery, valves, pumps and others Radiator, lamp shell, chair feet, meat slicer, antenna accessories, fan spindle pulley, motor base, special purpose.

Casting parameter

| Item | Casting Parts |

| Service | Process according to customer drawings |

| Process Technology | Gravity casting, shell mold casting, pressure casting Strong design team and computer ability, Pdf, auto CAD, solid works, CAXA, proe, Rhino, Catia, Simio, Alias, Arena were used by the R&D staffs during the design proess of new products. Surface anodizing/sandblasting, according to customer requirements |

| materials | Cast aluminum/cast iron/cast stainless steel, according to customer requirements |

| Product process | High pressure casting/low pressure casting/gravity casting/pressure casting, according to customer requirements |

Die casting customization process

1. Provide style and size (2D or 3D) or provide product samples.

2.After the production is completed, we arrange to ship.

3.Carry out mass production according to the detailed requirements of the order.

4. The customer needs to explain the product processing technology and surface treatment requirements, then we offer the price according to requirement.

5. The die casting department and mold department of the company conduct small batch trial production, and submit the order after confirmation by the customer.

FAQ

Q: Is it possible to know how are my products going on without visiting your company?

A: Yes, it is. After the cooperation is reached, we will plan a perfect production solution for you. The Quality inspection team will track the production process and give regular feedback on the production progress to you. Our factory will also provide pictures and videos at any time. We can also let you see the real status of the order production through video calls.

Q: Will my drawings be safe after sending them to you?

A: Sure. We have a strict privacy policy and will protect each customer's privacy information. It will only be given to the party you designate with your written permission. We are committed to protect customers’ privacy at all time. It is our obligatory responsibility to sign a NDA at customer’s request.

Q: What shall we do if we do not have drawings?

A: Don't worry. We have two ways to deal with it:

First, if you have product samples, you can send them to us, and we will measure the size for you after receiving the samples;

Second, you can provide product pictures or hand drawings with dimension marks. We will draw a drawing and send it to you for your approval.

Q: Are you a trading company or factory?

A: We are a comprehensive enterprise that not only has its own factory but also partner factories of the same standard as ours. It also has a complete supply chain, which can provide you with more comprehensive services.

OEM/ODM Casting service

Sino Industry and Trade Co., Ltd. is a leading foundry manufacturer specializing in the design, research, development, manufacture and marketing in the foundry industry in China. More than 40 years experience in casting/ forging/ machining industry, with 60 experienced technical engineers and 800 skilled workers, the company’s goal is to leverage its first-mover advantage in this field to support global low-carbon economic development. As a LEADER in the precision casting/ forging/ machining industry, as well as one professional OEM/ODM casting&forging manufacturer, we provide real one-stop service and optimal solution for customers. Our main products include but not limited to the following:

Ductile iron casting products, gray/ grey iron casting products, steel casting products, stainless steel casting products, carbon steel casting products, alloy steel casting products, sand casting products, die casting products, investment casting products, lost wax casting products, gravity casting products, vacuum casting products, etc. All castings are with precision CNC machining.

Application

Train, locomotive, railway, railroad, auto, car, truck, lorry, vehicle, machine, machinery, automotive, automobile, heavy-duty truck, transport truck, vehicle, forklift, farm vehicle/ machinery/ machine/ truck, agriculture/ agricultural vehicle/ machinery/ machine/ truck, combine harvester, tractor, trailer, mining equipment/ machinery/ machine/ truck/ vehicle, industry, device, facility, engine, etc.

About the delivery

1. To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided. Our packing uses export wooden cases, plastic boxes, cartons or pallets. All the package are very strong, the wooden box is firmly bound, the package is covered with a water-proof film to prevent water or damage during transportation. Before packing, we can also stick corresponding labels and shipping marks according to your needs. All our goods are well packed.

2. According to the quantity, we can use express delivery, air transportation or ocean transportation, automobile transportation, railway transportation, etc. we have our own freight forwarders, and we can also use the designated freight forwarders of customers, which can meet various delivery requirements of customers, such as EXW, FOB, CIF, etc.

3. We can also send the goods by express for a small order. According to customer's request, we can use Express such as DHL, TNT, EMS, FedEx, etc., the delivery time is 3-7. Safe, fast and convenient. It's also a good choice for you.