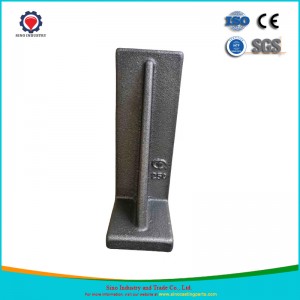

OEM Foundry Custom Casting Steel Parts with CNC Machining for Industrial Equipment

Product Details

| Our Steel Casting Production Ability: | |

| Procedure: | Sand casting, Lost wax casting(investment casting water glass process) & CNC machining |

| Steel Casting Tolerace: | CT8 |

| Roughness of steel casting parts: | Ra12.5 |

| Weight available: | 0.01kg - 3000kg |

| Dimension: | 4mm - 1200mm |

| Materials of steel casting parts: | Carbon steel,Alloy steel,Cast steel, Stainless steel,Cast iron,Ductile iron |

| Software Used: | Pro/E,Auto CAD,Solid work,UG,CAD,CAM |

| Steel casting Production Capacity: | 6000 tons per year |

| Samples Lead Time: | 15 days to 25 days |

| Testing offered | Chemical Composition Analysis |

| Machnical Property | |

| Metallograghic Analysis | |

| Magnetic Particle Inspection for carbon steel casting parts | |

| Penetrant inspection for stainless steel casting parts | |

| Ultrasonic Flaw Detection | |

| X-ray Detection | |

| Range of parts applied | Steel casting parts for Agricultural machinery,such as precision planter,cultivator and harvesting machine |

| Steel casting parts for Construction machinery,such as Excavator,Road roller, and auger attachments | |

| Steel casting parts for forklift truck and forllift attachment | |

| Steel casting parts for Forestry machinery,such as felling machine | |

| Steel casting parts for Hydraulic Parts, such as clevis head | |

| Steel casting parts for Truck parts and trailer parts | |

| Steel casting parts for Marine Hardware | |

| Steel casting parts for Oil & Gas Industry, such as cross coupling cable protectors | |

| Service offered | Precision Steel Casting designing |

| Casting parts production | |

| CNC precision machining from steel casting part or from raw material | |

| Heat treatment,such as annealling,tempering,quenching and tempering | |

| Surface finish,such as Zinc plating,Painting,E-coating,Hot dip Galvanizing | |

| Assembling | |

| Our Advantages | Rapid precision steel casting prototype within 15days to 22 days |

| Fast delivery,by using automatic lines for high volumes orders and using manual lines for small orders | |

| Joint work to optimize the desgin of steel casting parts, combined its' function and casting production,to reduce the weight and costs, and increase the effeciency and speed. | |

| Rich experience in casting production and low scrap rate and stable quality | |

| Wide range of material can be casted | |

| One stop custom made service from design to assembled parts | |

| Competitive Price and good services | |

Due to their increased strength and ductility, these types of castings are best used for:

| Valve Bodies | Compressor Valves | Couplings | Sprocket Wheels |

| Hydraulic Valves & Cylinders | Structural Brackets | Rollers | Cable Drums |

| Frames | Pumps | Crankshafts | Camshafts |

| Exhaust Manifolds | Machine frames | Flanges | Hubs |

| Gear Boxes |

Quality control

1. First-class equipments significantly improve production efficiency and product quality. Each batch of products from raw materials to finished products will be tested in the laboratory to ensure that the quality is up to the standards. Each batch of finished products will be carried out spectral inspection. For specific products tensile test will be conducted to ensure the tensile strength of products up to the standards.

2. Sample and pilot run will be given 100% inspection during production and before shipment, Sample check for mass production according to ISDO standard or customer requirements.

3. Test equipment: Spectrum Analyzer, CMM, Hardness test equipment, Tension test machine;

4. Modern machinery and patented equipment to improve production efficiency and ensure quality standards are met consistently.

5. Modern machinery and patented equipment to improve production efficiency and ensure quality standards are met consistently.

6. Use casting simulation analysis system software, try our best to ensure the success of one-time trial sample.

7. Advanced testing equipments, strict quality control system, to ensure us constantly, stably to provide high-quality products for customers.

Main Casting Products

Made in China Sand Casting Gearbox Transmissions Supplier Professional OEM/ODM Casting Factory

machinery components, machine components, industrial components, industry components, equipment components, mechanical components, machining components, cnc machining components, cnc components, precision components, high performance components, device components, facility components, engine components, motor components, precision machine components, valve components, valve body, valve shell, valve casing, valve housing, gate valve, ball valve, connector, solenoid valve, pipe fittings, control valve, floating ball valve, pneumatic valve, industrial valve, gas valve, flange gate valve, directional valve, hydraulic control valve, butterfly valve, gearbox, gearbox components, gearbox body, gearbox shell, gearbox casing, gearbox housing, oil cylinder, water pump, impeller, pump impeller, stainless steel pump, centrifugal pump, slurry pump, sewage pump, electric pump, submersible pump, high pressure pump, chemical pump, pressure pump, water pump set, self-priming pump, garden pump, deep well pump, oil pump, fountain pump, pond pump, mud pump, single suction pump, fuel pump, hydraulic pump, hydraulic pump components, hydraulic spare components, pump spare components, water pump components, diesel pump, vacuum pump, pump components, pump body, pump shell, pump housing, pump casing, pump cover, auto pump, car pump, automotive pump, automobile pump, vehicle pump, truck pump, lorry pump, farm machinery components, farm machine components, farm vehicle components, farm truck components, agricultural machinery components, agriculture machinery components, agricultural machine components, agriculture machine components, agricultural vehicle components, agriculture vehicle components, agricultural truck components, agriculture truck components, combine harvester components, mining machinery components, mining machine components, mining truck components, mining vehicle components, mining equipment components, machine spare components, hardware components, marine hardware, petrochemical components, petrochemical machine components, petrochemical machinery components, petrochemical equipment components, petrochemical device components, petrochemical facility components, petrochemical installation components, petroleum components, petroleum machine components, petroleum machinery components, petroleum equipment components, petroleum device components, petroleum facility components, petroleum installation components, energy components, energy machine components, energy machinery components, energy equipment components, energy device components, energy facility components, energy installation components, power machine components, power machinery components, power equipment components, power device components, power facility components, power installation components, power plant components, power plant machine components, power plant machinery components, power plant equipment components, power plant device components, power plant facility components, power plant installation components, shipbuilding components, shipbuilding machine components, shipbuilding machinery components, shipbuilding equipment components, shipbuilding device components, shipbuilding facility components, shipbuilding installation components, engineering components, engineering machine components, engineering machinery components, engineering equipment components, engineering device components, engineering facility components, engineering installation components, high quality components, high performance components, diesel engine, cast iron components, casting components, sand casting components, cast iron, cast steel, steel casting, iron casting, cast steel components, etc.

Our Services

1. Provide customized Sevice: could make product for customer according to customer samples or drawings.

2. Can deal with various drawings soft wares: PRO/E, Auto CAD, Slid Work, UG, etc.

3. Could offer samples for free.

4. Submit samples with official inspection reports including Material chemical compsition report, Mechanical Property report and dimensional report.

5. Can provide the Third Party Inspection Report.

6. PPAP documents are available.

7. Could provide at least one year quality guarantee after customer receives the products.

8. We could supply storage service for customer if required.

9. Leadtime: 20 days for samples, 30-45 days for production.

Procedures for Customizing Parts are as Follows

● Customer to provide 2D or 3D drawings;

● We quote the prices according to your drawings(we can also design the parts according to your specific requirements);

● Orders are confirmed by both parties;

● We start to put your parts into machining;

● We package and deliver the parts the customer;

● General Information of Our Products and Services;

Our advantages

1. Our company has professional engineering R&D department, mold department, stamping department, polishing department, quality inspection department, packaging department, sales department, after-sales department and other departments.

2. Our company has advanced and perfect precision casting supporting equipment, German spectrum analyzer and test equipment, metallographic microscope, 1200KN press and mechanical performance test equipment, multi-element analyzer, Richter hardness tester, helium pressure leak detector and other test equipment.

3. We can design molds and produce casting products according to customers' requirements, samples and drawings, and make all kinds of rough parts and finished parts.

4. We have matching production equipment, including rapid high-frequency melting furnace, resistance melting furnace, horizontal pouring machine, turnover pouring machine, low-pressure casting machine, quenching furnace, curing furnace, shot blasting machine, sand blasting machine, laser cutting machine, laser welding machine, ion cutting machine, CNC machining center, milling machine and other equipment.

FAQ

1: What are our Advantages over others?

a).We are the Manufacture,not a trading company, we can offer you a competitive price.

b).More than 40 years' Casting/Forging/Machining Experience.

f). We have sound business divisions including QC depart., Sales Depart., Engineer Depart., Shipping Depart., After-Sales,Depart., to serve you all the time.

2: What Production Equipments do you own?

CNC Machines, CNC Turning Machines, Auto-Lathes, Lathes, Drilling Machines, CD Texture Machines, Screw Cutting Machines,Diamond Cut Machines, Polising Machines, Gringding Machines, etc.

3: What Inspection Equipments do you have?

2D Project, Height Gages, Calipers, Thickness Machines, Hardness Machines, Microcallipers, spectral testing machine, tensile testing machine, etc.

4: What is your terms of payment?

Usually,we accept T/T, irrevocable L/C payable at sight. For regular orders, we prefer 30% in advance, 70% against the B/L. For long term business relations, we have more advantage terms for payment.

5: What is your terms of delivery?

We accept FOB, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

6: What is the lead time?

It usually takes 30 to 45 days after sample confirmation and receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. If the item was non standard, we have to consider extra 10-15days for tooling/mould made.

7: How about tooling Charge?

Tooling charge only charge once when first order, all future orders would not charge again even tooling repair or under maintenance.

8: What is your sample policy?

Samples cost generally can be refunded if your quantity can meet our MOQ.

9: Can you provide OEM/ODM servie according to samples or drawings?

Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.